Band Saw Blade Manufacturer

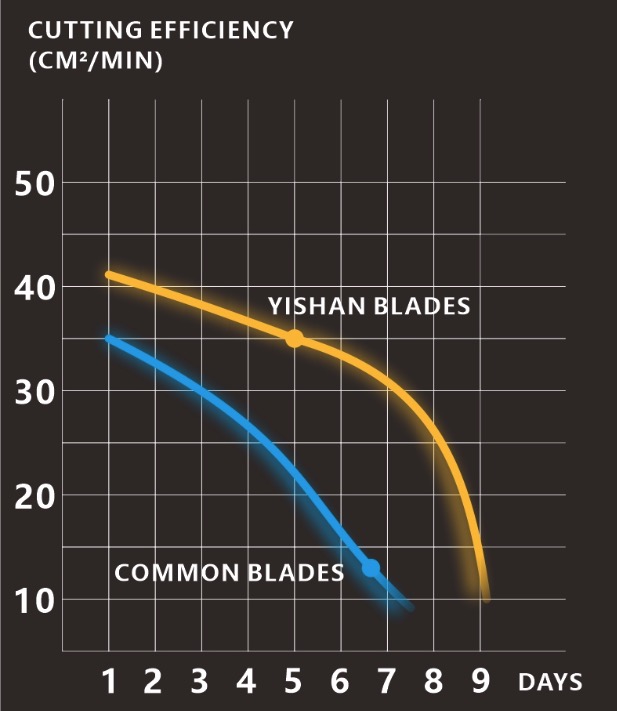

Get 53% Longer Lifespan Bi-Metal Bandsaw Blades – Precision Engineered for YOUR Industry.

Frequent blade breakage

42 minutes wasted every 8-hour

Our solution: YISHAN M42+ bimetal band saw blade

You Gain: ▼30% downtime → Continuous cutting time extended to 8.5 hours

Inconsistent cut quality

Our solution: AI-optimized width-to-TPI matching

You Gain:▲18% throughput

Hidden cost black hole

Poor quality blades lead to workpiece rework rate exceeding 6.2%

Our solution: ±0.03mm cutting accuracy guarantee

You Gain: Contracted customers' processing scrap rate ▼ 50%

Expert advice

Our guarantee: 48x7h engineer on call +

2-hour response SLA for on-site problems

Meters of band saw blades delivered this quarter

What Top-Tier Manufacturers Achieved

Automotive Gearbox Producer

– Challenge: 43% scrap rate on 42CrMo4 shafts

– Our Fix: 41mm TCBEdge blades with Variable tooth design

– Results:

▶ 0.02mm positional accuracy

▶ $15.8K annual savings

▶ 17% faster cycle times

Food processing plant

– Challenge: Rough cutting surface affects the yield rate

–Our Fix:Tooth shape optimization

– Results:

▼Meat processing loss rate reduced by 22%

▲2.3kg more

Case 3: Sawmill Manufacturer

– Disaster: Frequent machine stops for tool changes

– Our Fix: Top quality steel, first-class equipment

– Results:

▲30% life than traditional bandsaw blades

▶Annual replacement cost savings of $12,000

Case 4: Aircraft Landing Gear Manufacturer

– Disaster: Failed 78% of FAA hardness tests

– Our Fix: 27mm vacuum-hardened blades

– Results:

▶ 99% metallurgical integrity

▶ 30% longer blade lifespan

▶ 10 fewer calibration stops/month

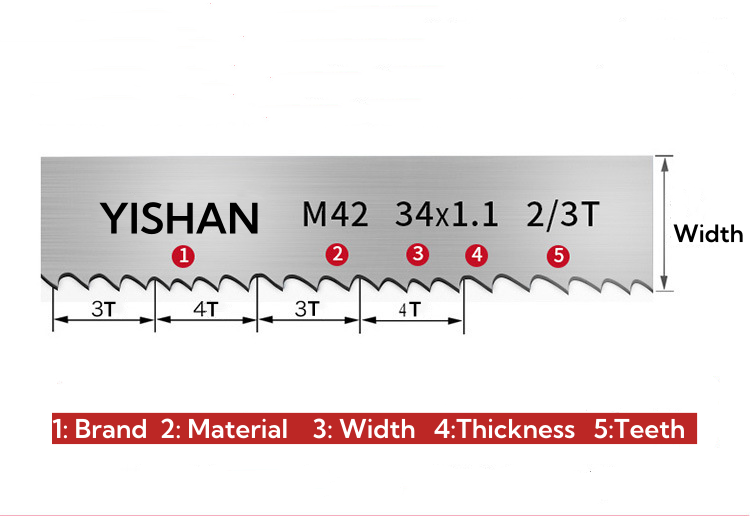

Start to Customize

Please input details to get a quick quote.

Furnished in welded bands, random length coils, and 100-metre coils

Note: Special products on request

Get Up Close and Personal with Our High-Quality Band Saw Blade

See to Believe!

Won’t believe your eyes! Our stunning photos showcase every angle and detail of our reliable metal cutting band saw blade. As an import customer, you can’t afford to miss out on these jaw-dropping visuals. See to believe!

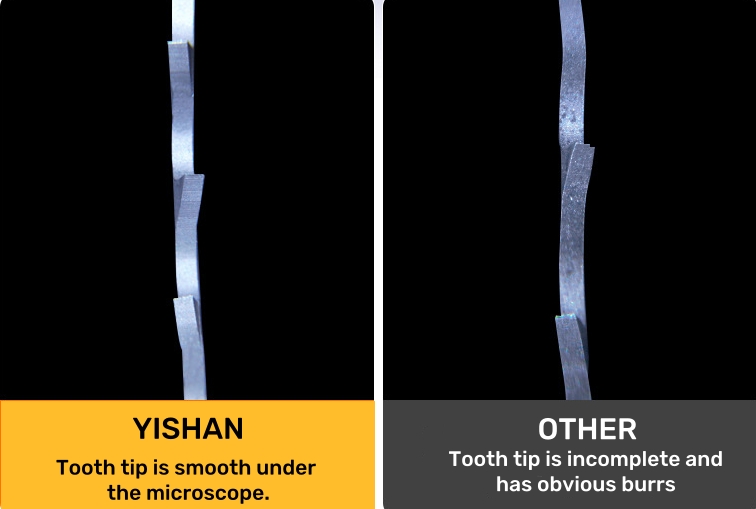

Sharp Teeth

Made of top carbon steel, the tooth tip hardness HRC67-72, can easily cope with all kinds of processing scenarios.

Seamless Weld

IDEAL machine and welders with 10 years of rich experience ensure that each of your saw blade welds is flat and firm.

Grinding Teeth

The precision grinding technology between teeth improves the equal height and finish of the tooth tip, improves the wear resistance of the tooth tip.

Advanced Equipment

World’s leading application technology of separate heat treatment in tooth material and backing material.

Straightening Machine

It optimizes blade precision and factory productivity.

Not sure what you need?

No problem – we understand every business is different. Reach out to us, and we’ll help you find the perfect product tailored to your needs.

Cutting Cases

Check out the cutting power in action! We have photos and videos submitted by customers showing you real-life cutting situations using our high-quality band saw blade for metal. Seeing is believing!

What Clients Are Saying

“Sharpness and durability are crucial for us, and this bone saw blade exceeded expectations. After weeks of use, it still feels brand new. Fast delivery was a lifesaver when we needed it urgently. We’re sticking with YISHAN for sure!”

Carlos M.

Wholesale

“Product quality is very stable, and our customers are very satisfied. The cooperation in the supply is also very timely, and we have never encountered out-of-stock problems.”

Ali

Distributor

“Since we switched to this band saw blade, downtime has been reduced by 50% and productivity has increased significantly. And have never encountered any quality problems.”

John

A large manufacturing company