M51 Band Saw Blade

Searching for exceptional quality in M51 bandsaw blades? With YISHANHN, you receive dependable performance, fast delivery, and unbeatable value. Our commitment to custom solutions ensures your specific needs are met with blades engineered for superior cutting efficiency and extended lifespan. Trust YISHANHN to deliver premium bandsaw blades that drive your business forward with confidence and success.

Your Go-To Source for M51 Band Saw Blade

Welcome to YISHANHN, your reliable source for premium M51 bandsaw blades, celebrated for their precision and unmatched durability. Our blades are expertly crafted to enhance efficiency and minimize downtime, making them the top choice for distributors and agents serving high-demand industries.

Discover our wide range of blade options, including different widths, tooth configurations, and materials, tailored to meet the varied cutting needs of your customers. Whether you supply blades for metalworking, woodworking, or construction, our products deliver consistent, efficient results to keep operations running seamlessly.

Rely on YISHANHN for top-quality bandsaw blades that elevate performance across industries. Partner with us to offer reliable, long-lasting cutting solutions that drive your business success.

M51 Bimetal Band Saw Blade

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Customize Band Saw Blade for Your Cutting!

At YISHAN, we recognize the critical need for reliable, high-performance M51 band saw blades designed to meet your market demands. As a trusted leader in bandsaw blade manufacturing, we provide precise customization and quick delivery to match your exact requirements. Our dedication to quality guarantees top-tier products, supported by expert technical assistance to help you achieve success with every cut.

Our metal bandsaw blades are available in durable M42, M51 and Carbide options, customized to fit your specific applications and maximize blade lifespan.

13 x 0.65mm

19 x 0.9mm

27 x 0.9mm

34 x 1.1mm

41 x 1.3mm

54 x 1.6mm

67 x 1.6mm

80 x 1.6mm

0.75/1.25 1/1.5 1.4/2. 1.7/2.5. 2/3

3/4 4/6 5/8 6/10 8/12 10/14 14/18

- Uncoated: Standard option for general-purpose cutting.

- TiN Coating: Increases surface hardness and wear resistance, good for cutting abrasive materials.

- TiCN Coating: Enhanced wear resistance, suitable for cutting hard and abrasive metals.

- Customized to fit specific band saw machines.

- Available in pre-cut lengths or in bulk coil form (e.g.,50meters,100 meters coils) for on-site cutting.

Why YISHAN Is Your Ideal Partner For M51 Band Saw Blade

Choosing YISHAN means partnering with a manufacturer dedicated to the success of your projects involving M51 band saw blades. What sets us apart is not only our industry expertise but also our commitment to delivering exceptional value to you:

- Tailored Excellence: Your projects demand precision and quality, which is why our team at YISHAN focuses on crafting bandsaw blade solutions that meet your exact needs. Your success reflects our craftsmanship, commitment, and dedication to delivering the best.

- Cost Efficiency for You: We understand the importance of budget-friendly solutions. By leveraging competitive material sourcing, we provide you with high-quality M51 band saw blades at cost-effective prices, giving you a strong advantage in your market.

- Guaranteed Satisfaction: Your priorities are at the core of our business. We prioritize clear communication and deliver solutions that exceed expectations, ensuring your experience with us is consistently outstanding.

With YISHAN, you get more than just a supplier—you gain a committed partner invested in your success, providing tailored solutions that enhance your efficiency and profitability.

Your Ultimate Guide to Procuring M51 Band Saw Blades

Selecting the right M51 band saw blades for your specific applications can be challenging, especially in demanding fields like metalworking and woodworking. YISHAN is here to simplify the process. Our expert team provides tailored guidance to help you choose the optimal blades for your project’s needs, guaranteeing maximum cutting efficiency and extended durability. Let us help you find the perfect M51 band saw blades, ensuring a smooth, hassle-free selection experience that meets your unique requirements.

Chapter 1

What is a M51 Band Saw Blade

An M51 band saw blade is a high-performance cutting tool made with M51 steel hich contains around 10% cobalt (Co) and 10% tungsten (W). This provides excellent wear resistance and hot hardness.

- Durability: Excellent for cutting high-strength materials like stainless steel, tool steel, and nickel alloys.

- Heat Resistance: The cobalt and tungsten content makes it suitable for high-temperature applications.

- Extended Blade Life: Reduced wear rate compared to standard bi-metal blades (e.g., M42 blades).

In summary, M51 band saw blades are the go-to choice for cutting tough materials where standard M42 blades may fail.

Chapter 2

Key Features of M51 Band Saw Blade

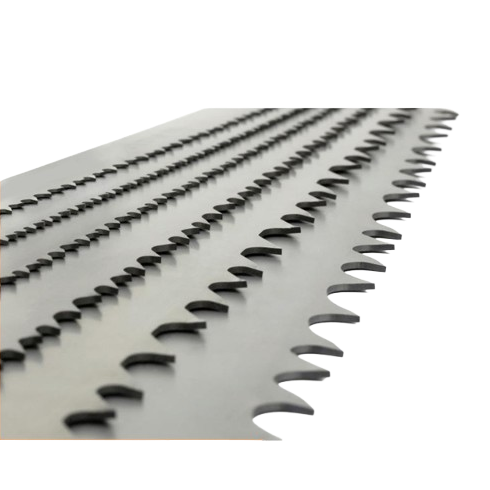

Exceptional Wear Resistance

- The M51 tooth edge is made with high-speed steel containing 10% cobalt and 10% tungsten, giving it excellent wear resistance and longer life, even when cutting tough materials.

Superior Heat Resistance

- The alloy composition (with cobalt and tungsten) provides enhanced hot hardness, allowing the blade to maintain its cutting efficiency even under high-temperature conditions.

High Durability

- The tooth edge can handle high cutting forces and resist chipping, making it ideal for cutting tough alloys like Inconel, titanium, and tool steels.

Optimized Tooth Geometry

- M51 blades typically feature special tooth profiles (e.g., variable pitch) that reduce vibration, provide smoother cuts, and enhance blade life.

Flexible Backing Material

- The backing material is usually spring steel, which offers excellent flexibility and fatigue resistance, allowing the blade to withstand heavy-duty cutting applications.

Extended Blade Life

- M51 blades generally last up to 2-3 times longer than standard M42 bi-metal blades, providing better cost efficiency in the long run.

Best Applications

High-alloy steels (e.g., tool steel, stainless steel)

Exotic alloys (e.g., Inconel, Monel, titanium)

Hard-to-machine metals in aerospace, automotive, and heavy fabrication industries.

In summary, the M51 band saw blade is engineered for extreme durability and performance, making it a premium choice for cutting challenging and high-hardness materials.

Chapter 3

M51 Band Saw Blade Specifications

| Specification | Details |

|---|---|

| Tooth Material | M51 high-speed steel (contains ~10% cobalt, ~10% tungsten) |

| Backing Material | High alloy steel ( flexibility and fatigue resistance) |

| Hardness (Tooth Tip) | 67-69 HRC |

| Hardness (Backing) | 38-42 HRC |

| Heat Resistance | Excellent; retains hardness and cutting efficiency at high temperatures |

| Wear Resistance | Very high, ideal for hard materials and abrasive metals |

| Tooth Geometry | Variable pitch, designed to reduce vibration and enhance cutting performance |

| Typical Blade Widths | 27 mm, 34 mm, 41 mm, 54 mm, 67 mm,80mm |

| Typical Blade Thickness | 0.9 mm, 1.1 mm, 1.3 mm,1.6mm |

| Cutting Applications | High-alloy steels, stainless steel, Inconel, Monel, titanium, tool steels |

| Industries | Aerospace, automotive, heavy-duty metal fabrication |

| Expected Blade Life | Up to 2-3 times longer than M42 bi-metal blades when cutting hard materials |

This table highlights the key features that make M51 band saw blades suitable for heavy-duty cutting in challenging environments.

Chapter 4

Applications of M51 Band Saw Blade

Cutting High-Alloy Steels and Tool Steels M51 band saw blades are the preferred choice for cutting high-alloy steels such as D2, H13, and other tool steels. The high cobalt content (10%) provides superior wear resistance, making it suitable for cutting hard materials that would typically dull standard blades quickly.

Machining Stainless Steel With its excellent heat resistance and durable tooth edge, the M51 blade can efficiently cut through various grades of stainless steel (e.g., 304, 316, 17-4PH). The blade maintains its hardness at high temperatures, reducing the risk of premature wear or tooth chipping.

Processing Exotic Alloys (Inconel, Titanium) The M51 band saw blade is highly effective for cutting exotic alloys like Inconel, Monel, and titanium. These materials are known for their toughness and resistance to wear, but the robust design of M51 blades handles the challenge, providing clean and consistent cuts without excessive tool wear.

Heavy-Duty Metal Fabrication In heavy-duty metalworking applications, such as aerospace and automotive industries, M51 blades excel due to their durability and ability to withstand high cutting forces. This makes them ideal for tasks like cutting thick bars, billets, and tubes.

Production Cutting in Manufacturing M51 blades are widely used in production environments where continuous cutting of hard materials is required. Their extended lifespan and reduced downtime make them cost-effective for manufacturers dealing with demanding cutting jobs.

In summary, the M51 band saw blade is designed for high-performance cutting of tough, heat-resistant, and wear-resistant materials, providing reliable service across a wide range of industrial applications。

Chapter 5

Customization M51 Band Saw Blade Options

| Customization Option | Details |

|---|---|

| Tooth Pitch (TPI) | Variable tooth pitches (e.g., 2/3, 3/4, 4/6 TPI) for optimizing cutting speed and reducing vibration based on material thickness. |

| Blade Width | Custom widths available (from 13 mm to 80 mm) to suit different cutting machines and applications. |

| Blade Thickness | Options range from 0.5 mm to 1.6 mm, depending on the material to be cut and the cutting conditions. |

| Tooth Shape | Various tooth profiles (standard, variable) tailored to specific cutting needs and materials. |

| Coating Options | Optional coatings (TiN, TiAlN) for enhanced wear resistance and reduced friction, especially for high-temperature applications. |

| Length | Custom blade lengths available to fit different band saw machines, from small workshop saws to large industrial saws. |

| Set Type | Custom tooth set options (raker set, alternate set, wavy set) for optimized chip removal and cutting efficiency. |

| Material Grades | Tailored M51 alloy composition based on the specific requirements (e.g., higher cobalt content for enhanced heat resistance). |

| Marking and Branding | Custom blade markings and logos for private labeling or company branding. |

These customization options allow users to optimize the 51 band saw blade for specific cutting tasks and machinery, enhancing performance and longevity.

Chapter 6

Maintenance and Care of M51 Band Saw Blade

M51 band saw blades, made from M51 high-speed steel with higher cobalt (10%) and tungsten content, are designed for cutting extremely hard and heat-resistant materials. Proper care and maintenance are essential to maximize their performance and lifespan.

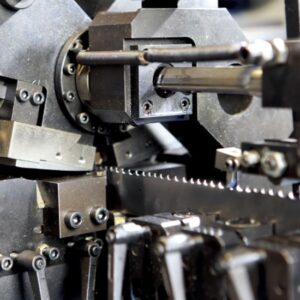

1. Proper Blade Tensioning

Follow the manufacturer’s tension specifications to avoid blade deformation or breakage.

Over-tensioning can lead to fatigue and premature failure, while under-tensioning may result in slippage and inaccurate cuts.

2. Break-In Procedure

Start with a lower feed rate (50% of normal) for the first 20-30 cuts with a new blade.

This allows the teeth to smooth out, reducing the risk of chipping and increasing blade life.

3. Regular Cleaning

Clean the blade teeth after each use to remove metal chips and debris. Buildup can cause tooth wear, overheating, and blade damage.

Use a brush or compressed air for effective cleaning.

4. Lubrication and Cooling

Apply coolant or cutting fluid, especially when cutting hard metals like Inconel, titanium, or hardened steels.

This reduces friction, prevents overheating, and helps maintain the blade’s hardness and sharpness.

5. Monitor for Wear and Damage

Regularly inspect the blade for signs of wear (e.g., rounded teeth), cracks, or tooth chipping.

Replace the blade promptly if damage is observed to prevent further issues and ensure consistent cutting quality.

6. Ensure Proper Blade Alignment

Misalignment of blade guides or machine wheels can cause uneven cuts and excessive stress on the blade.

Regularly check and adjust alignment to prevent twisting or bending of the blade.

7. Use Appropriate Cutting Speed and Feed Rate

Adjust the speed and feed rate based on the material’s hardness and thickness.

Excessive speed or pressure can lead to tooth breakage, while too slow a feed rate may cause the blade to rub, generating excess heat.

8. Avoid Excessive Vibration

Secure the workpiece properly to minimize vibration during cutting.

Excessive vibration can damage the blade teeth and reduce cut quality.

9. Proper Storage

Store the blades in a clean, dry environment to prevent rust and corrosion.

Hang the blades or coil them loosely to avoid bending or kinking.

10. Regular Machine Maintenance

Keep the band saw machine in good condition. Ensure guides, wheels, and other components are well-maintained.

A poorly maintained machine can cause unnecessary wear on the blade.

For best performance, always use the M51 blade within its recommended parameters, especially when cutting difficult materials. Proper care and adherence to guidelines will help you get the most out of this high-performance blade, reducing downtime and replacement costs.

Chapter 7

How to Find a Reliable M51 Band Saw Blade Manufacturer?

When searching for a reliable M51 band saw blade manufacturer, it’s essential to consider several key factors to ensure you get high-quality products and consistent service. Here are the main points to help you make an informed decision:

1. Check Product Quality and Certifications

Look for manufacturers that use high-grade M51 high-speed steel with certified cobalt and tungsten content. Reliable manufacturers often provide material certifications and ISO quality management system certifications (e.g., ISO 9001).

Ask for product samples or data sheets to verify hardness, durability, and cutting performance.

2. Experience and Expertise in the Industry

Choose a manufacturer with years of experience in producing band saw blades, especially for industrial applications. Experienced companies typically have in-depth knowledge of tooth design, heat treatment, and blade construction, which are crucial for M51 blades.

A strong track record in the market and positive feedback from existing customers can be a good indicator of reliability.

3. Custom Solutions and Technical Support

A good manufacturer should offer customized blade specifications based on your specific cutting requirements (e.g., blade width, tooth pitch, and geometry).

Ensure they provide technical support, including guidance on blade selection, usage, and troubleshooting.

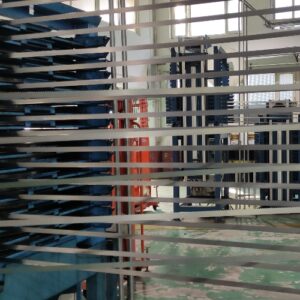

4. Consistent Supply and Inventory Availability

Reliable manufacturers maintain a stable supply chain and sufficient inventory to meet your needs, especially if you require large or frequent orders.

Check if they have a distribution network that can deliver products quickly and efficiently, reducing lead times.

5. Competitive Pricing and Value

While price is important, avoid the trap of choosing the cheapest option. Low-cost blades may not meet performance expectations, leading to frequent replacements and downtime.

Look for manufacturers that offer a good balance of price and quality, with blades that provide longer life and better cutting performance, reducing overall costs in the long term.

6. Customer Reviews and Reputation

Read customer reviews and case studies to gauge the manufacturer’s reputation. Positive feedback from reputable companies in industries like aerospace, automotive, and metal fabrication is a strong indicator of reliability.

Look for manufacturers that are recommended by industry professionals or have partnerships with well-known machine tool companies.

A reliable M51 band saw blade manufacturer will offer high-quality products, provide excellent technical support, maintain a consistent supply, and have a proven track record in the industry. Take the time to evaluate potential suppliers carefully, and prioritize quality and expertise to ensure the best results for your cutting applications.

Chapter 8

Precautions for Using M51 Band Saw Blade

Proper usage of the M51 band saw blade is crucial for maximizing its performance and lifespan, especially when cutting tough and abrasive materials. Here are key precautions to consider:

1. Proper Break-In Procedure

Perform a break-in process when using a new M51 band saw blade. Start with reduced feed rate (50-70% of normal) and low cutting pressure for the first few cuts. This helps the teeth form correctly, preventing premature chipping or wear.

2. Ensure Correct Blade Tension

Set the blade tension according to the manufacturer’s specifications, typically around 250-300 N/mm². Insufficient tension can cause the blade to slip or produce inaccurate cuts, while excessive tension may lead to blade breakage.

3. Optimize Cutting Speed and Feed Rate

Adjust the cutting speed and feed rate based on the material hardness and cross-sectional area. For tougher materials (e.g., Inconel, stainless steel), use a lower speed to reduce heat and wear. Refer to recommended speed charts for M51 blades for optimal settings.

4. Use Proper Coolant/Lubrication

Always use an appropriate coolant or lubricant when cutting with M51 blades. This helps reduce heat buildup, minimizes wear, and extends blade life. Ensure the coolant flow is adequate and consistent throughout the cut.

5. Check Blade Alignment

Misalignment can lead to uneven wear and poor cutting performance. Regularly inspect and adjust the band saw guide, blade tracking, and alignment to ensure the blade runs smoothly and straight.

6. Avoid Cutting Material Beyond Blade Capacity

Do not use the M51 blade on materials or dimensions it’s not rated for. Cutting materials that are too hard or thick without proper settings can result in tooth damage or breakage.

7. Regular Blade Maintenance

Clean the blade after use to remove debris and metal shavings. Regular inspections help detect early signs of wear, tooth damage, or fatigue, allowing for timely replacement before failure.

8. Ensure Proper Storage

Store M51 band saw blades in a dry, cool environment. Avoid moisture to prevent rust on the backing material. Use blade racks or coil the blade correctly to prevent kinks and maintain its integrity.

Following these precautions can help you get the best performance out of your M51 band saw blade. Proper break-in, tensioning, speed control, and maintenance are key to extending blade life and achieving consistent, high-quality cuts.

Chapter 9

In summary

The M51 band saw blade is a high-performance bi-metal blade designed for cutting tough and hard-to-machine materials. It features a tooth tip made from M51 high-speed steel, which contains approximately 10% cobalt and 10% tungsten, providing exceptional wear resistance, heat resistance, and cutting durability. The flexible backing is typically made of high-strength spring steel, offering excellent fatigue resistance.

Boost Your Projects M51 Band Saw Blade !

Whatever your bi-metal bandsaw blade needs, our expertise guarantees precision-engineered solutions tailored to your specifications. By sourcing high-quality raw materials and maintaining rigorous quality control, we deliver exceptional blade performance and longevity. Plus, our streamlined production process allows us to offer competitive pricing, giving you unbeatable value and reliability.