You want to reshape your memory foam mattress, but the task feels complicated. Are you worried about rough edges or wasted material? Let me help.

Cutting a memory foam mattress is easier when you have the right tools. A band knife, circular blade, or even an ultrasonic cutter can ensure smooth edges. Proper preparation, stable cutting speed, and consistent pressure also matter. This helps you get a neat finish without damaging the foam.

Cutting Memory Foam Mattress

Cutting Memory Foam Mattress

I know that buyers like you want a cost-effective way to handle memory foam cutting. Many of my customers worry about the final result. Let’s explore the best methods and tools for this process.

What is the best tool for cutting a foam mattress?

You might feel annoyed about rough or jagged cuts when dealing with foam. Do you want a tool that gives a clean, precise line without creating a mess?

The best tool for cutting a foam mattress varies by production volume. For large projects, mechanical cutters like a band knife or circular blade can work best. Smaller tasks may need a simple handheld solution.

Tool for Cutting Foam Mattress

Understanding Mechanical vs. Thermal and Other Options

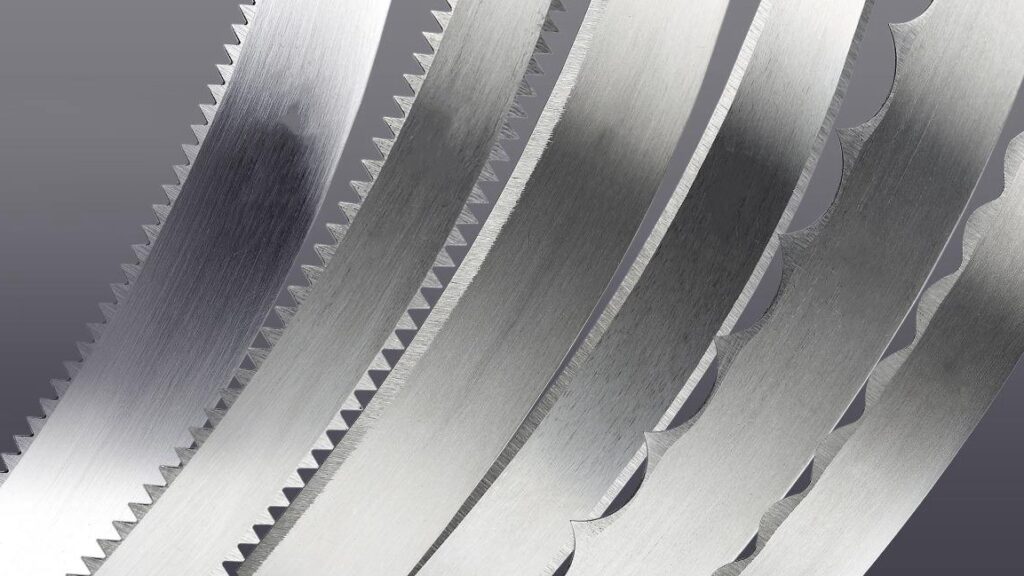

Mechanical cutting tools are popular for foam mattresses because they are versatile and easy to find. Circular blades, band knives, and reciprocating saws all fall under this category. Each has its pros and cons, but they share a basic principle: they use physical force or a rotating or moving blade to slice through the foam.

I often recommend circular foam cutting machine if you have large quantities of foam and need speed more than precision. These machines spin at high speed and cut thick foam efficiently. Yet, they might leave a slightly uneven edge if the blade is not steady.

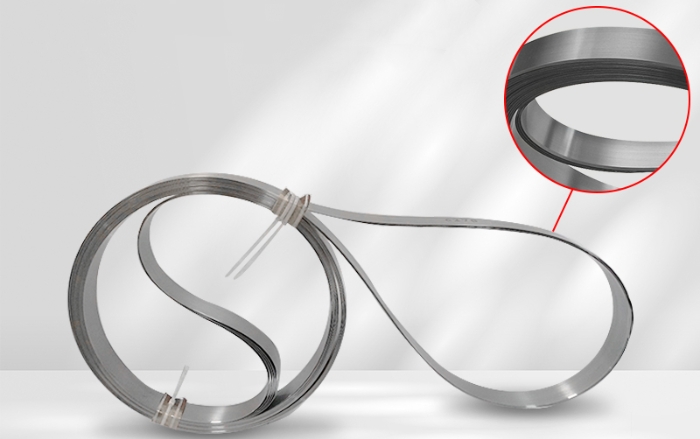

Vertical / Horizontal foam cutting machine, however, offer higher precision. A band knife has a continuous blade loop that moves in one direction, giving a clean line with less debris. This method suits buyers who want a smoother finish, especially if they need a neat, uniform edge. If you have a bigger workshop with a steady workload of foam, band knives can save time and money in the long run.

Vertical foam cutting machine

Vertical foam cutting machine

Reciprocating saws are another mechanical choice. They are flexible and can handle tight spaces or smaller jobs. You can maneuver them around curves, though it can take more practice to maintain a clean edge. Reciprocating saws also work well if you have limited space, because they are compact and portable. However, you may notice that the cut is less smooth than with a band knife.

Thermal methods include hot wire cutters and hot air cutters. These tools melt the foam along the cutting line. A hot wire cutter uses a thin wire with electric current running through it, while a hot air cutter uses a stream of very hot air. These options give a decent finish but are slower. They also produce fumes, so you need proper ventilation. If you have detailed shapes to cut or you want minimal foam waste, thermal methods might be good, though they are more common with rigid foams rather than soft memory foam.

Ultrasonic cutting is another option, though the machine cost is high. This tool uses high-frequency vibration to melt and slice through foam. It leaves a very clean edge, but the price can be tough to justify unless you have a large-scale operation with strict precision needs.

Hand tools are the simplest approach. A utility knife or even an electric carving knife can do smaller jobs. If you only need to trim a corner or cut a single mattress, this might be your cheapest option. The downside is that manual cuts can become uneven if you rush or apply too much pressure.

So, the best tool depends on your production scale, budget, and quality needs. Buyers with a high production volume often invest in more advanced machines. Smaller businesses or home users might do fine with a handheld knife. In my own factory, I use band knives for precision and speed, but I also keep a smaller reciprocating saw for quick modifications. I like that combination because it covers most cutting tasks without wasting foam or leaving big messes on the shop floor.

How do you cut a foam mattress easily?

Do you find thick memory foam mattresses intimidating? You might feel unsure if a simpler method exists. Let me share a few tips to keep it easy.

To cut a foam mattress easily, you need a stable workspace, a sharp cutting tool, and a steady approach. A slow, controlled method prevents ragged edges and wasted foam.

Easy Foam Cutting

Steps for a Smooth Cut

I have cut many foam mattresses for different customer projects. I learned that preparation is often the key to an easy cut.

-

First, lay your foam mattress on a flat surface. Check for lumps, bumps, or foreign objects. Even small debris can cause jagged edges.

-

Then, measure and mark your cutting line. Use a straightedge or a long ruler to draw a guide. Some people skip this step, but I find it saves time because you avoid guesswork. Also, make sure your cutting surface is safe. You want to avoid damaging the floor or the table beneath the foam.

-

Next, choose your tool. For easy cutting, I often grab a utility knife if the foam is not too thick. I make a shallow cut first to create a guide, then I go deeper. This reduces friction and helps me maintain a straight line. If you need a faster cut and you have access to an electric carving knife, that’s also a good choice. Keep your hands firm and try not to rush.

Cutting speed matters. If you cut too fast, the blade may bind or tear the foam. If you cut too slowly, you risk creating a jagged line or straining your wrist. A steady, moderate pace is best. If you hear strange sounds or notice the blade straining, adjust your speed.

Some buyers, like Dianel, need to cut many foam mattresses for their business. In that case, a mechanical cutter saves time. A simple circular blade setup can slice through multiple layers, though you must be careful about alignment. If you only have a small workshop, you can start with a reciprocating saw. Just clamp the mattress in place, follow your guide marks, and keep the saw at a consistent angle.

Finally, inspect your cut. Look for uneven areas, and if needed, use a knife to trim. Clean the edges if you notice little foam crumbs. The end result should be neat and ready for use or resale.

What is the best tool with which to cut foam?

Have you considered the wide range of foam cutting solutions but still feel confused? Maybe the variety of mechanical, thermal, and ultrasonic options leaves you uncertain.

The best tool depends on your needs. High-volume production calls for a band knife blade. Smaller or custom jobs do well with handheld electric knives or a reciprocating saw.

Foam Cutting Tool Options

Foam Cutting Tool Options

Comparing Common Foam Cutting Tools

I often see buyers struggle to decide which tool to invest in. I like to break down the options in a simple way. Each tool differs in speed, precision, and cost.

| Tool | Speed | Precision | Cost | Best For |

|---|---|---|---|---|

| Circular foam cutting machine | High | Medium | Medium | Large volumes, quick slicing |

| Vertical/Horizontal foam cutting machine | High | High | Medium to High | Complex shapes, smooth edges |

| Reciprocating Saw | Medium | Medium | Low to Medium | Small workshops, easy curves |

| Hot Wire Cutter | Low | High | Medium | Detailed shapes, slower pace |

| Ultrasonic Cutter | High | Very High | High | High-end, precise projects |

| Handheld Knife | Low | Low to Medium | Very Low | One-time cuts, simple tasks |

Circular foam cutting machine use a spinning blade to slice through foam. They are fast but can create a rougher edge.Vertical/Horizontal foam cutting machine blade have a continuous, thin blade loop that offers more control and a smoother finish. Reciprocating saws are a middle ground with decent speed and moderate precision, which might be best if you have limited space and want to save money.

Thermal cutting tools include hot wire and hot air cutters. These tools melt foam along the cutting line. The result can be cleaner, but the process is slower than mechanical cutting. Ultrasonic cutting vibrates at high frequency to slice foam with minimal distortion, though it requires a bigger investment. Handheld knives and electric carving knives are the most budget-friendly solutions. They offer freedom of movement but can produce less uniform results.

I often suggest that buyers think about their budget and production scale. If you run a large factory in need of standard shapes, you might invest in a specialized mechanical machine or even a CNC system. If you handle smaller orders or custom shapes, you could consider a band knife or a hot wire setup. The main takeaway is to match your cutting tool to your foam thickness, desired shape, and your production goals.

How to cleanly cut memory foam?

Do you want edges so smooth that you can place a cover on the mattress without lumps? Clean cuts are essential for a professional look and for ensuring the foam remains intact.

To cut memory foam cleanly, use a consistent cutting speed, a sharp blade, and careful alignment. This approach reduces tearing and keeps edges uniform.

Clean Memory Foam Edges

Techniques for a Flawless Finish

Buyers often ask me about the secret to a flawless cut. I learned that the secret lies in preparation, blade maintenance, and steady operation. Memory foam is sensitive to uneven force because it is softer and can deform under pressure. If you push too hard, you will compress the foam and create an uneven cut line.

-

First, choose a blade suited for memory foam. A band knife with a fine serration can handle the soft material without tearing. Some factories use an ultrasonic cutter for memory foam because it does not rely on brute force. The high-frequency vibration slices the foam at the molecular level, leaving a perfectly smooth edge. However, ultrasonic machines can be expensive if your operation is small.

-

Second, consider your cutting environment. If your shop is too hot or too cold, memory foam might change in density. Extreme temperatures can make the foam stiffer or softer. A moderate indoor temperature helps maintain consistent behavior. Keep the foam on a stable surface that does not shift or bounce when you apply pressure.

-

Third, plan your cut. Mark your lines with a simple marker or chalk. If you are using a band knife machine, make sure the tension on the blade is correct. Loose tension can cause a wavy cut. Also, feed the foam at a steady pace. Some operators push the foam too fast to save time. This can cause the blade to shift or tear the foam. Others move too slowly and risk partial melting or shredding.

-

Fourth, handle any leftover scraps properly. Sometimes small bits of foam remain stuck to the blade. Clean them away between cuts. This prevents buildup that can lead to uneven edges on your next cut. Also, wearing protective gear is wise. Even though memory foam is soft, you want to avoid accidents and keep your environment tidy.

-

Finally, check your final result. I like to run my hand along the edge to feel for bumps. If I see or feel imperfections, I trim them with a small handheld knife. This final step ensures that the mattress has a consistent shape. Buyers appreciate a neat finish, and it reflects positively on your brand.

Conclusion

Clean, efficient cuts on memory foam mattresses are possible when you match the right tool and method to your specific needs. A stable approach, consistent speed, and proper blade choice lead to professional results every time.