Are your band saw blades dulling quickly, costing you time and money? This constant replacement cycle hurts your bottom line. You can fix this with a few key techniques.

To reduce band saw blade wear, you must select the right blade for your material, ensure correct blade tension, use proper cutting speeds and feeds, and apply coolant. Regular machine maintenance and operator training are also critical for extending blade life and improving overall efficiency.

It seems straightforward, but I've seen so many workshops get these details wrong. Small mistakes add up to big costs in blade replacements and lost production time. But don't worry, we can fix that. Let's dig into the practical steps you can take today. By the end of this, you'll have a clear plan to make your blades last longer and cut better.

What are the most effective ways to stop your band saw blades from wearing down?

You keep buying new blades, and the cost just keeps adding up. This downtime for blade changes is frustrating and kills your production schedule. Let's stop this wasteful cycle.

To stop blades from wearing down, focus on the fundamentals. Choose the right blade for the job. Install it with the correct tension. Use the manufacturer's recommended speeds and always use lubrication. Finally, keep your machine clean and don't overload the blade. These steps are simple but powerful.

Let's dive deeper into how you can make a real difference in your blade life. I've organized my thoughts into three main areas: the blade itself, how you operate the machine, and your maintenance routine. Getting these right is the secret to durability. I remember a client who was changing blades daily on a tough stainless steel job. We spent an afternoon just focusing on these basics, and they started getting a full week out of each blade.

Blade Selection and Setup: Your First Line of Defense

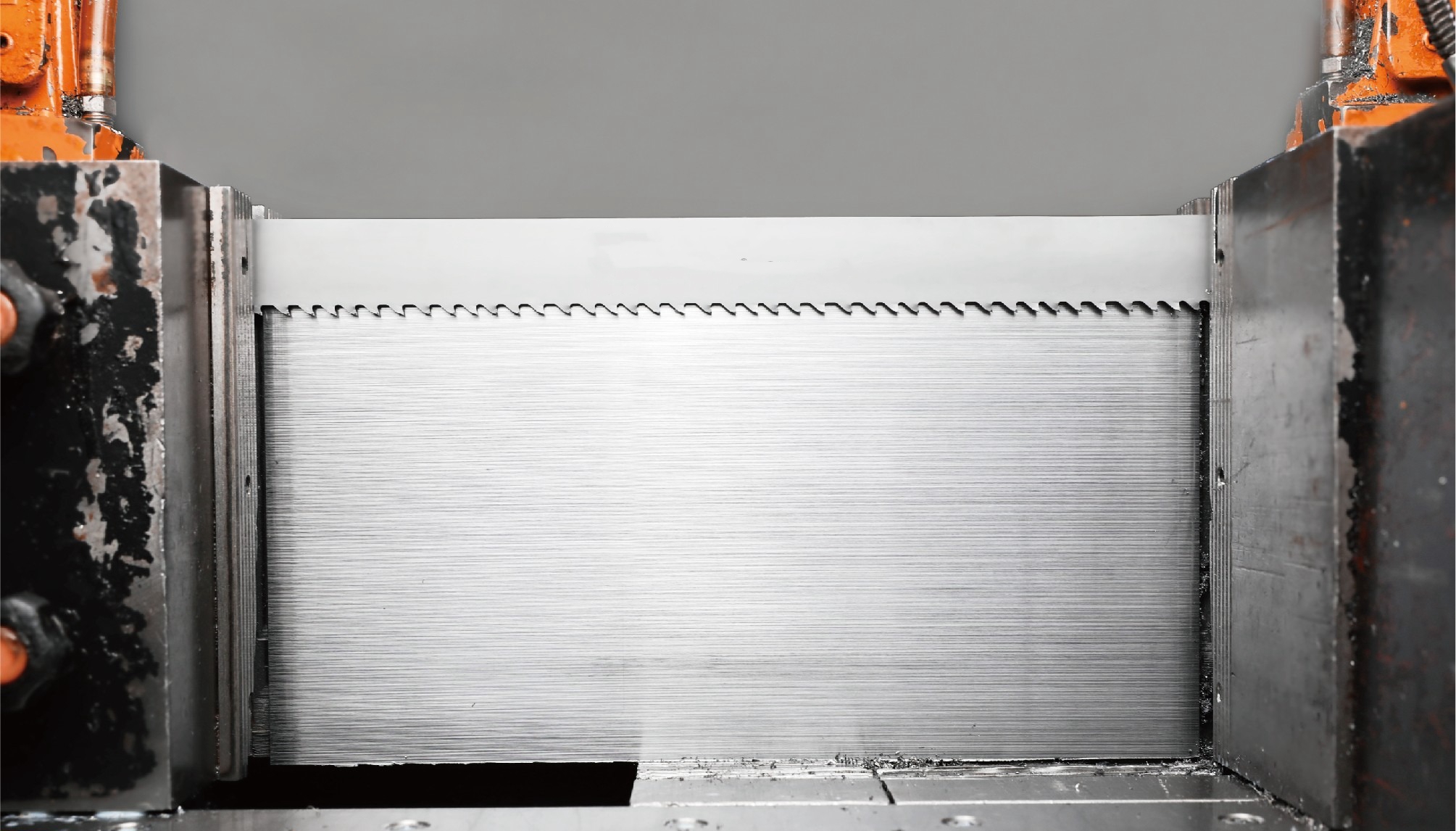

Choosing the right blade is more than just finding one that fits. You need to match the blade's material, tooth shape, and teeth per inch (TPI) to the material you are cutting. A bimetal blade is great for general-purpose cutting, but you might need a carbide-tipped blade for very hard or abrasive materials. Using the wrong blade is like trying to chop a tree with a butter knife. It will wear out fast and do a poor job. Equally important is the installation. Blade tension is critical. If it's too loose, the blade will wander and cut crookedly, causing uneven wear on the sides of the teeth. If it's too tight, you put immense stress on the blade's body, which can lead to premature cracks and failure long before the teeth are dull. Always use a tension gauge and follow the manufacturer's specifications.

Operational Discipline: Speed, Feed, and Lubrication

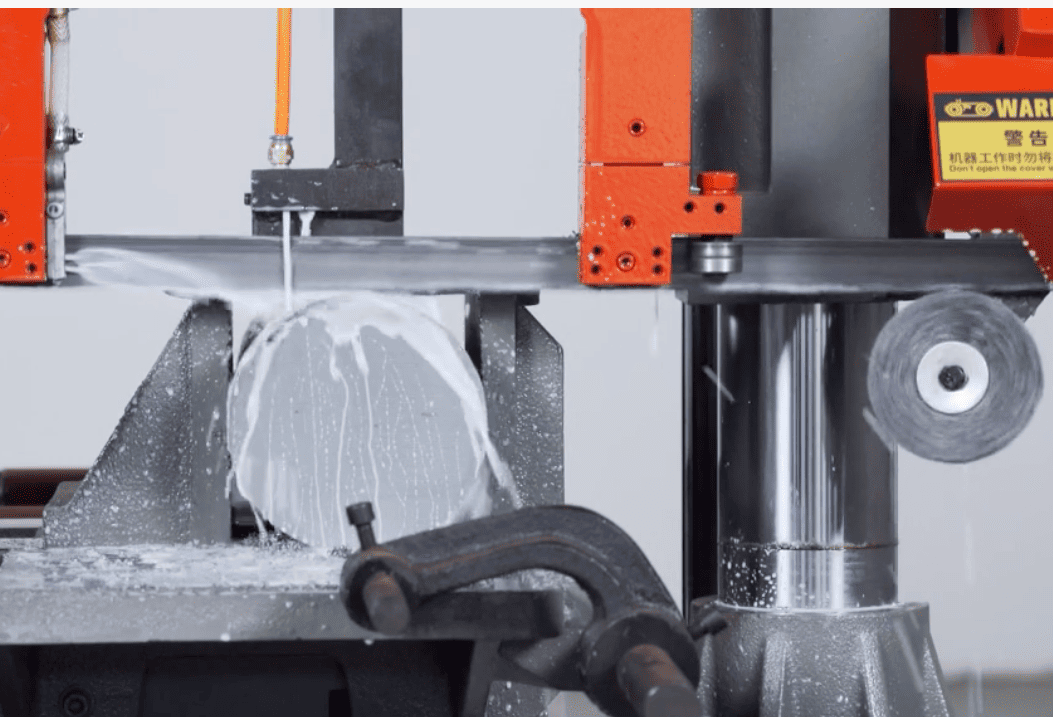

How you cut is just as important as what you cut with. Every material has an ideal cutting speed. Cutting too fast generates excessive heat, which softens the blade's teeth and makes them wear down incredibly quickly. Cutting too slowly can cause work hardening in some materials, making the next cut even harder. You also need to control the feed pressure. Pushing too hard overloads the teeth and can cause them to strip or chip. Pushing too lightly causes the teeth to rub instead of cut, which also generates heat and dulls the blade. And never forget lubrication. Coolant does two things: it reduces heat and it helps flush chips out of the cut. If chips get packed in the blade's gullets, they create friction, heat, and can even cause the blade to bind and break.

Key Factors for Blade Longevity

| Factor | Bad Practice (Causes Wear) | Good Practice (Extends Life) |

|---|---|---|

| Selection | Using a one-size-fits-all blade | Matching blade material and TPI to the workpiece |

| Tension | Guessing the tension ("good enough") | Using a gauge to set the correct tension |

| Speed | Always running at maximum speed | Adjusting speed based on the material chart |

| Lubrication | Cutting dry or with low coolant flow | Maintaining a steady flood of clean coolant |

| Load | Forcing the blade through the material | Applying steady, appropriate feed pressure |

How can you improve your sawing efficiency without just cutting faster?

Your cutting process feels slow, and work is piling up. This bottleneck delays orders and drives up labor costs per part. You can boost your output with a few smart adjustments.

To improve sawing efficiency, focus on optimizing the entire process. Plan the shortest cutting path, clamp your workpiece securely to prevent vibration, and apply the correct feed pressure. Regular machine maintenance and proper operator training will also significantly increase your output.

Making your operation more efficient isn't just about cranking up the speed dial. In fact, that's often the wrong move. True efficiency comes from being smooth, stable, and smart. It’s about removing wasted time and motion from the process. I've worked with factories that doubled their cutting output not by buying a faster machine, but by rethinking their workflow from the ground up. Small changes in setup and operation can lead to massive gains in the number of parts you produce each day.

Workflow Optimization: Planning and Clamping

Before the blade even touches the metal, you can find efficiency. Plan your cutting path. If you are making multiple cuts on a single piece, figure out the sequence that requires the least amount of material movement. For multiple small parts, consider stack cutting or bundle cutting. Cutting ten pieces at once is far more efficient than cutting one piece ten times. The next critical step is clamping. The workpiece must be held absolutely rigid. Any vibration or movement during the cut forces the operator to slow down the feed rate. A vibrating workpiece also causes chatter, which is bad for blade life and surface finish. Use proper clamps, vices, and supports to ensure your material is locked down tight. A stable setup allows for a confident, consistent, and faster feed rate, which is the heart of efficient cutting.

Feed Pressure and Machine Health: The Power Duo

The best way to judge your cutting efficiency is by looking at the chips. The chips tell you everything about your feed pressure and blade condition. Ideally, you want to see thin, curled, silver chips. This indicates the blade's teeth are penetrating the material and removing it cleanly. If you see dust or fine powder, your feed pressure is too low. The teeth are rubbing, not cutting, which is very inefficient and dulls the blade. If you see thick, blue, or burnt-looking chips, your feed pressure is too high or your speed is too fast, creating too much heat. You need to train your operators to "read the chips" and adjust the feed pressure accordingly. This can only be done effectively if the machine itself is in good health. A worn-out hydraulic system or a faulty feed control cannot maintain consistent pressure, making efficient cutting impossible. Regular machine maintenance is a direct investment in your productivity.

Efficiency Improvement Checklist

| Area | Action Item | Why It Boosts Efficiency |

|---|---|---|

| Path | Plan the shortest cutting route or bundle parts | Reduces non-cutting time and blade travel |

| Clamping | Ensure the workpiece is completely stable | Allows for higher, consistent feed rates without chatter |

| Feed Rate | Adjust pressure to produce well-formed chips | Ensures the blade is cutting at its optimal removal rate |

| Tools | Use roller tables and laser guides | Speeds up material handling and alignment |

| Training | Teach operators to monitor the cut by sight and sound | Enables real-time adjustments for a faster, smoother process |

Conclusion

By focusing on correct blade selection, proper machine setup, and disciplined operation, you will significantly reduce blade wear. Smart workflow and operator training will boost your overall sawing efficiency and profitability.