Bimetal Band Saw Blade

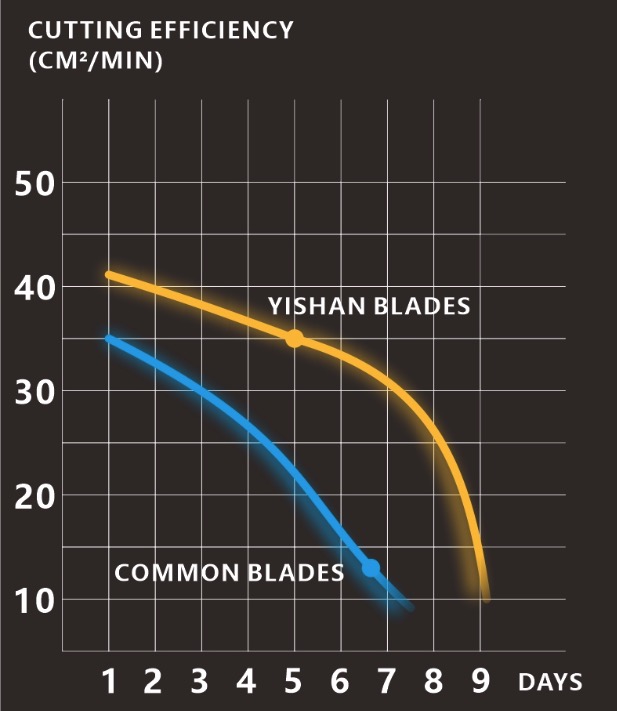

Get 53% Longer Lifespan Bi-Metal Bandsaw Blades – Precision Engineered for YOUR Industry.

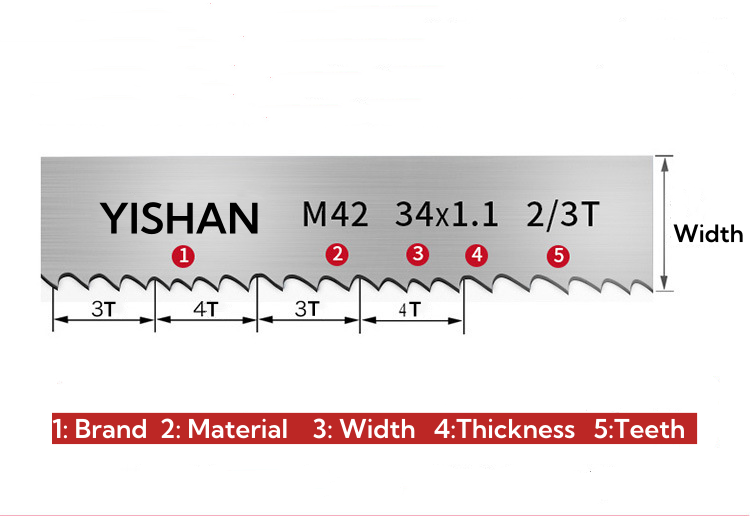

10 Product Series 47 Tooth Shapes

When your production needs to cut everything from carbon steel to titanium alloys, you need band saw blades that deliver consistent performance — without compromise.

YISHAN offers 10 complete product series and 47 different tooth forms, built to handle a wide range of materials: stainless steel, aluminum alloy, nickel-based alloy, bronze, copper, titanium, and more.

No matter what you cut, we have a blade that fits — precisely.

Frequent blade breakage

42 minutes wasted every 8-hour

Our solution: YISHAN M42+ bimetal band saw blade

You Gain: ▼30% downtime → Continuous cutting time extended to 8.5 hours

Inconsistent cut quality

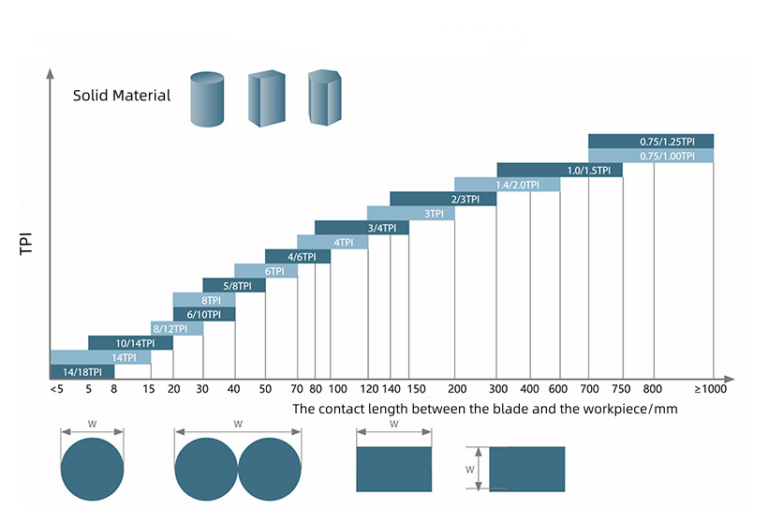

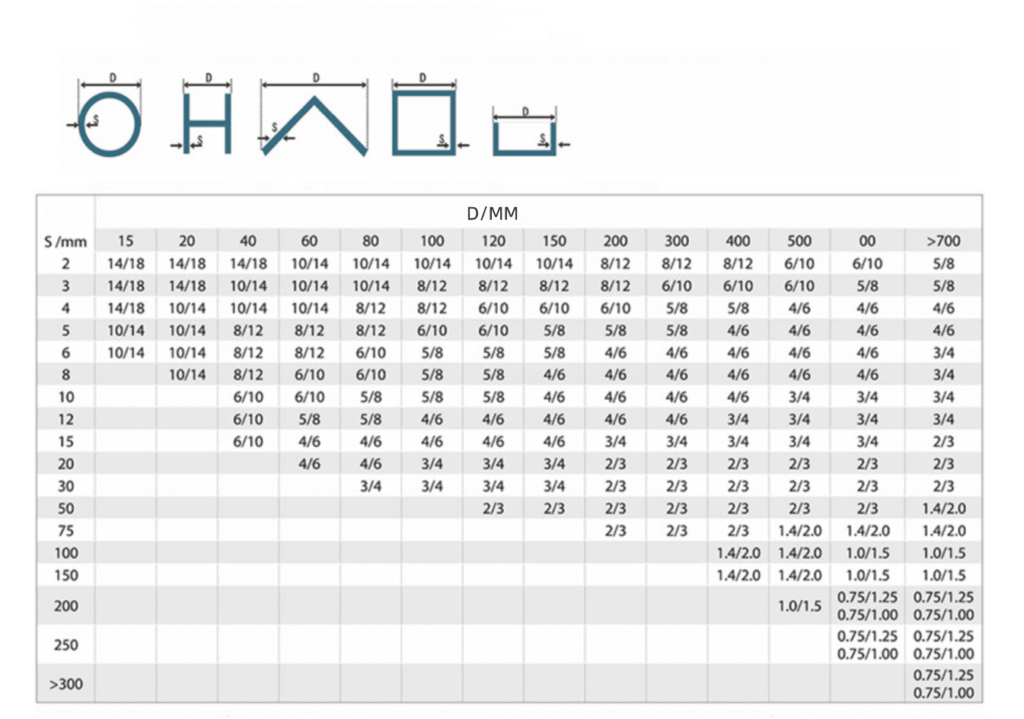

Our solution: AI-optimized width-to-TPI matching

You Gain:▲25% throughput

Hidden cost black hole

Poor quality blades lead to workpiece rework rate exceeding 6.2%

Our solution: ±0.03mm cutting accuracy guarantee

You Gain: Contracted customers' processing scrap rate ▼ 50%

What Sets Us Apart

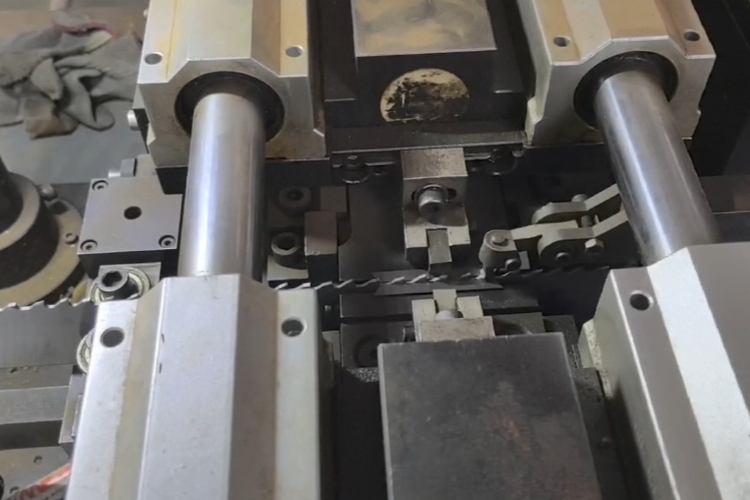

High-End Equipment

We’ve invested in Germany full-automatic lines, milling production, and grinding welding processing workshops — all under one roof.

Better Margins

Thanks to our bulk raw material purchasing and fully-integrated factory, we offer prices up to 10% lower than competitors — without cutting corners.

Full Support & Service

From pre-sales to manufacture and after-sales, we will provide the tailored solution according to your cutting scenarios and quote within 24 hours

Meters of bimetal band saw blades delivered this quarter

What Top-Tier Manufacturers Achieved

Automotive Gearbox Producer

– Challenge: 43% scrap rate on 42CrMo4 shafts

– Our Fix: 41mm TCBEdge blades with Variable tooth design

– Results:

▶ 0.02mm positional accuracy

▶ $15.8K annual savings

▶ 17% faster cycle times

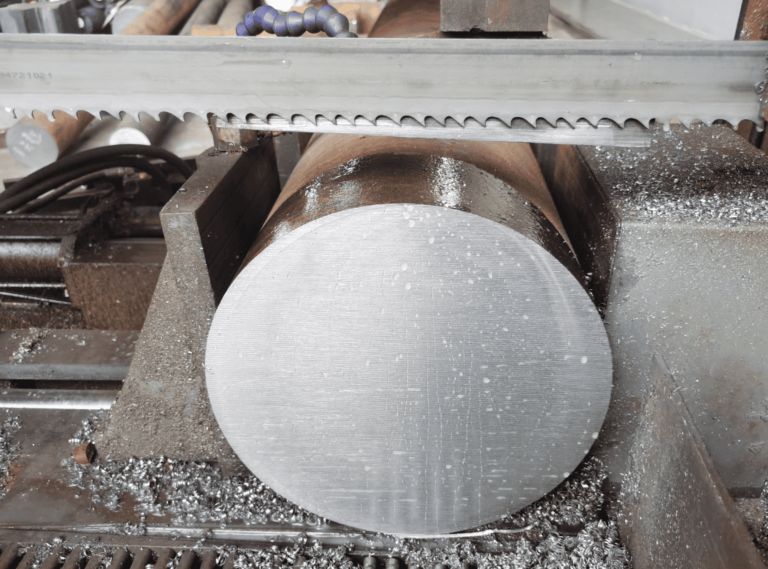

Titanium alloy machining center

– Cutting material: TC4 Φ720mm

– Results:

– Line speed: 30 m/min

– Cutting efficiency: 12 cm²/min

– Single blade life: 4 hours

– Cutting life: 27 cut blades

Case 3: Sawmill Manufacturer

– Disaster: Frequent machine stops for tool changes

– Our Fix: Top quality steel, first-class equipment

– Results:

▲30% life than traditional bandsaw blades

▶Annual replacement cost savings of $12,000

Case 4: Aircraft Landing Gear Manufacturer

– Disaster: Failed 78% of FAA hardness tests

– Our Fix: 27mm vacuum-hardened blades

– Results:

▶ 99% metallurgical integrity

▶ 30% longer blade lifespan

▶ 10 fewer calibration stops/month

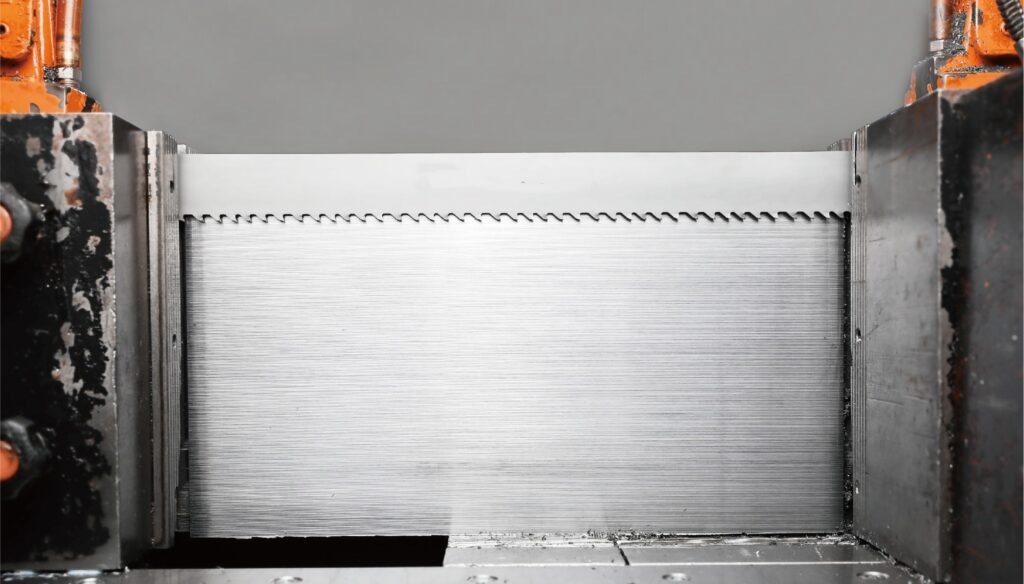

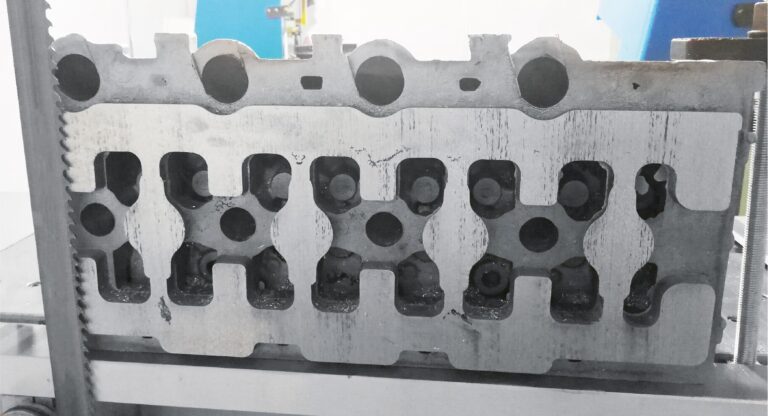

Case 3: Automotive parts manufacturer

– Cutting material: Engine cylinder head AlSi6Cu4

– Results:

-Line speed: 1750m/min

-Feed speed:450mm/min

-Cutting life:12,865 pieces

Start to Customize

Please input details to get a quick quote.

Furnished in welded bands, random length coils, and 100-metre coils

Note: Special products on request

Get Up Close and Personal with Our High-Quality Band Saw Blade

See to Believe!

Won’t believe your eyes! Our stunning photos showcase every angle and detail of our reliable metal cutting band saw blade. As an import customer, you can’t afford to miss out on these jaw-dropping visuals. See to believe!

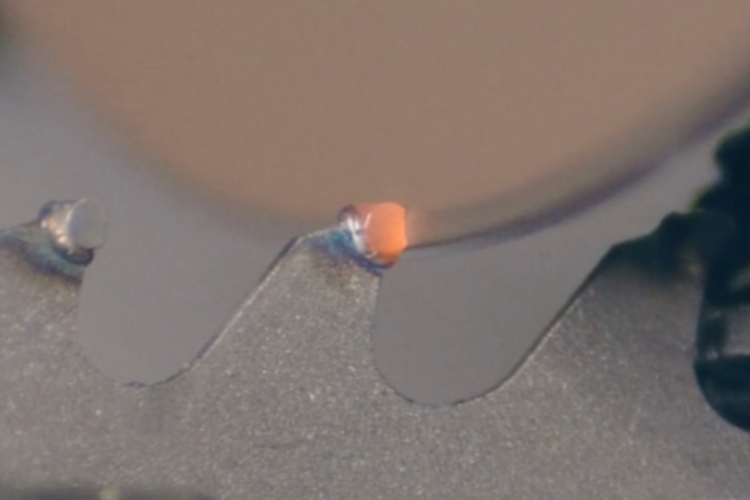

Oil quenching and tempering

Leading oil quenching and continuous tempering technol- ogies extremely improved the hardness of the tooth and the wear resistance of backing material.

High cutting efficiency

YISHAN’s proprietary heat treatment technology tackles blade warping, S-bends, and poor cut quality, these issues at the root, ensuring stable blade shape, clean cuts, and higher cutting efficiency across every application.

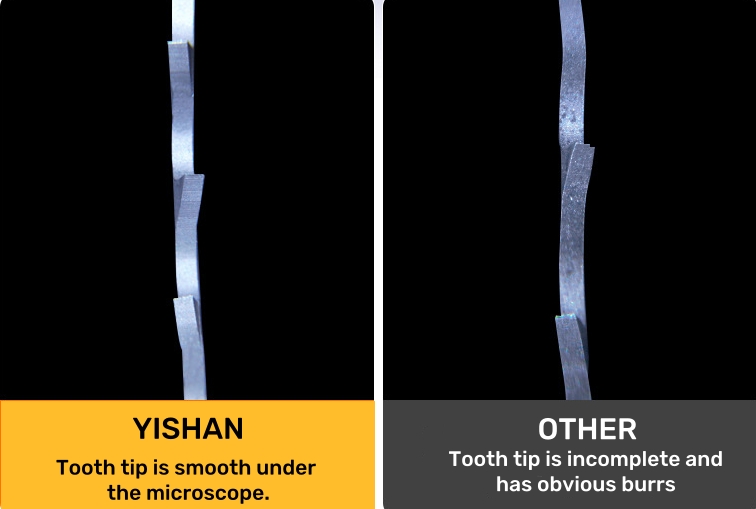

Cleaner Cuts Less Downtime

Uneven tooth height, dull tips, and poor chip removal can kill your cutting efficiency.

YISHAN uses precision tooth grinding technology to ensure uniform height, razor-sharp edges, and high surface finish — all of which improve tooth wear resistance and allow for smooth chip evacuation.

Precision Guarantee

YISHAN’s precision tooth splitting technique ensures better surface finish and tight geometric tolerances at the sawing point — giving you cleaner cuts, less rework, and more consistent results every time.

Precision Guarantee

grinding wheel precision sharpening to reduce cutting resistance.

Smooth, polished tooth surfaces that extend service life

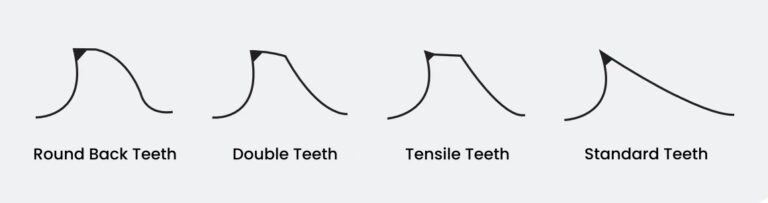

Flexible tooth profiles you can choose based on the materials you cut

Fast, Flexible Shipping

We partner with trusted logistics providers to give you fast delivery at competitive rates. Orders are packed securely in tubes, boxes, or pallets, and custom crating is available on request.

Choosing the Right Bimetal Band Saw Blade

You don’t just want a band saw blade that cuts. You want a blade that lasts longer, works faster, and keeps your production line safe and efficient — without pushing up your costs.

That’s why the right blade selection matters.

Cutting hard alloys or stainless steel? You’ll need blades with higher wear resistance to handle the job.

Common Tooth type

Solid material

Pipes and Metal Profiles

Not sure what you need?

No problem – we understand every business is different. Reach out to us, and we’ll help you find the perfect product tailored to your needs.

What Clients Are Saying

“Sharpness and durability are crucial for us, and this bone saw blade exceeded expectations. After weeks of use, it still feels brand new. Fast delivery was a lifesaver when we needed it urgently. We’re sticking with YISHAN for sure!”

Carlos M.

Wholesale

“We used to work with several suppliers from Europe and Korea, but prices were too high and delivery took forever. With YISHAN, not only did we reduce our costs by 30%, but the quality is even better. Our clients are happy, and so are we.”

Alexander

Purchasing Manager

“Product quality is very stable, and our customers are very satisfied. The cooperation in the supply is also very timely, and we have never encountered out-of-stock problems.”

Ali

Distributor

“In our market, things move fast and price pressure is real. YISHAN gets it. They offer consistent quality, support OEM logos, and always ship on time. That’s exactly what I need to stay ahead of local competition..”

Tim

Business Owner

“Since we switched to this band saw blade, downtime has been reduced by 50% and productivity has increased significantly. And have never encountered any quality problems.”

John

A large manufacturing company

“We tested YISHAN’s bimetal band saw blades alongside German ones, and the results were impressive. Smooth cutting, long lifespan, and no breakage issues. Plus, the cost savings help improve our margins.”

Anna

Export Manager

No pressure. No charge. No hassle. Let’s get to know each other better.