Cutting polyurethane foam might seem like a simple task, but without the right tools, it can quickly turn into a frustrating experience. Are you struggling with clean, precise cuts? You’re not alone.

Polyurethane foam is a versatile material used in various industries, but cutting it efficiently and cleanly requires the right approach and tools.

Cutting Polyurethane Foam

Cutting foam can be tricky, but knowing the different types of foam and the tools needed can make the job much easier. Let’s dive into the details of how to cut polyurethane foam effectively.

What is the easiest way to cut polyurethane foam?

Cutting foam doesn’t have to be complicated, but choosing the wrong tools can make it messy and frustrating. The easiest way to cut polyurethane foam1 is by using a sharp, fine-toothed saw or knife blade.

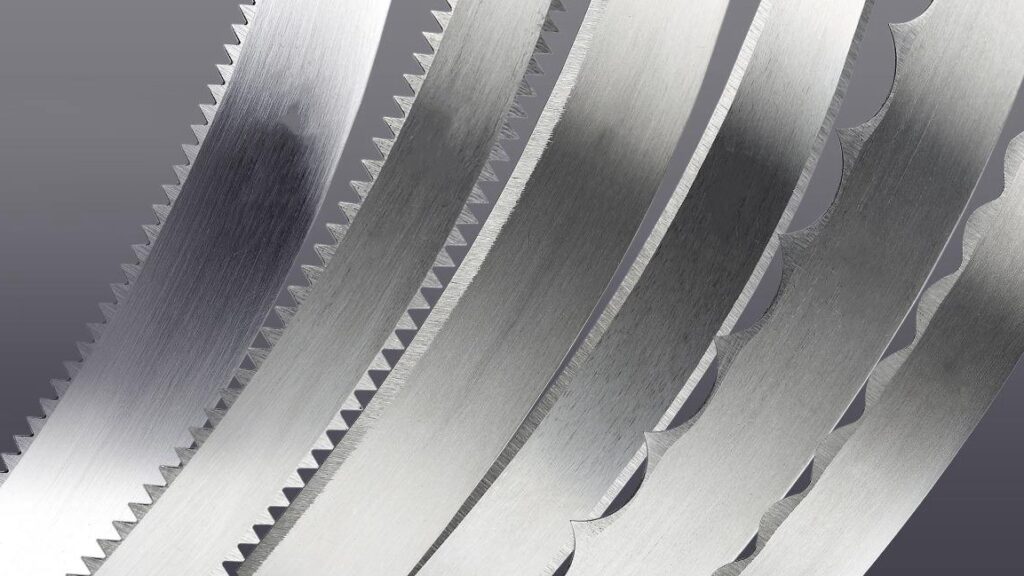

The easiest way to cut polyurethane foam is to use a straight band knife2 or band knife blade with teeth for softer varieties. For denser foam, a sharper, more precise tool is ideal.

Cutting Tools for Foam

Cutting polyurethane foam can be simple, depending on the type and density of the foam. If you have the right tool, you can achieve smooth, clean cuts. Let’s take a deeper look into the different tools and techniques that can make foam cutting easier.

Different Types of Polyurethane Foam and Their Cutting Tools

Polyurethane foam comes in various densities and types, each requiring specific tools for optimal cutting. Below is a breakdown of some common types:

Soft, Low-Density Polyurethane Foam

This foam is typically used in furniture cushions, mattresses, and medical seating applications. The low density allows it to be cut with simpler tools. For this type, a straight band knife blade or serrated knife works well. These tools provide a clean cut without much force.

High-Density Polyurethane Foam

Used in applications that require more support, like high-quality mattresses or automotive seating, high-density polyurethane foam needs a bit more precision. For this type, a V-shaped or Scallop-shaped band knife blade3 provides the necessary cutting power.

CNC Blades for Profiling

When cutting polyurethane foam for custom shapes, CNC blades are a great option. These blades are designed for contour cutting and are particularly effective for creating precise shapes or complex profiles in foam.

Manual Cutting Methods

Manual cutting is an option, though it may not provide the cleanest results. While using a serrated knife or handsaw might work in a pinch, the edges tend to be rough, especially for higher-density foam. It’s a good choice for quick, rough cuts but not for fine-tuned work.

What is the best tool to cut poly foam?

Choosing the best tool for cutting poly foam comes down to the foam’s density. For softer foams, a straight knife or electric carving knife is the best choice. For tougher, denser foams, however, specialized blades are required.

The best tool for cutting polyurethane foam is a straight band knife blade for softer foam, while denser foam requires a fan or V-shaped band knife blade.

Best Tools for Cutting Polyurethane Foam

Having the right tool makes a world of difference when it comes to clean and precise cuts. Let’s explore the tools in more detail to find the best one for your specific needs.

Tools for Soft and Low-Density Polyurethane Foam

For softer, low-density polyurethane foam, a straight band knife blade is the best option. This tool is widely used for cutting foam into basic shapes, such as those needed for mattress padding, cushions, and medical applications. The straight edge of the knife allows for smooth, clean cuts without much resistance.

Electric Knives

An electric carving knife can also be used for soft foam. These knives feature serrated blades that can slice through foam with minimal effort. While this tool is easy to use and great for quick cuts, it might not be the best for precision cutting.

Tools for High-Density Polyurethane Foam

When dealing with denser polyurethane foam, a more robust tool is needed. A fan or V-shaped band knife blade is designed specifically for this purpose. These blades have teeth that help cut through the foam with ease while leaving a cleaner edge than a manual saw or knife.

CNC Blades

If you need to cut foam into specific shapes or profiles, a CNC machine with the right blade is your best option. CNC blades offer unmatched precision and can handle high-density foam without causing jagged edges or rough cuts.

Manual Cutting for Small Jobs

While manual cutting may not be the most efficient for larger projects, it’s still a viable option for smaller jobs. You can use a sharp utility knife or serrated blade to make clean cuts on polyurethane foam, but the process is slower and requires more effort.

What is the best tool to cut polyurethane?

When cutting polyurethane foam, it’s crucial to choose the right tool based on the foam’s density and the job’s complexity. For general cutting, a straight band knife blade or serrated blade works well, but for detailed cuts, specialized tools like CNC blades are best.

The best tool for cutting polyurethane foam is a straight or serrated band knife blade for general cutting. For more detailed or complex cuts, consider using CNC blades.

Polyurethane Foam Cutting Tools

Choosing the correct tool ensures that your cuts are accurate and clean. Let’s look at how these tools compare and how to select the right one for your project.

Comparing Cutting Tools for Polyurethane Foam

Here’s a comparison of the cutting tools most commonly used for polyurethane foam, helping you choose the one that best fits your needs:

| Tool Type | Best for | Key Features |

|---|---|---|

| Straight Band Knife | Soft, low-density foam | Clean, smooth cuts for general applications |

| Scallop or V-shaped Blade | High-density foam | Provides a clean edge on tougher foam |

| CNC Blade | Contour or profile cutting | High precision for complex shapes |

| Electric Knife | Soft foam, quick cuts | Fast and easy, but less precise |

How to cleanly cut soft foam?

When working with soft foam, the key to a clean cut lies in using the right tool and technique. A straight band knife or serrated knife should provide clean cuts with minimal mess.

To cleanly cut soft foam, use a straight band knife or electric carving knife, ensuring a smooth, straight cut.

Clean Cut Polyurethane Foam

Cleaning up the edges is just as important as making the initial cut. To help you achieve smooth, professional cuts, here are some tips on how to cut soft foam cleanly.

Cutting Techniques for Clean Edges

The process of making a clean cut starts with selecting the right tool. A straight band knife blade is best for achieving smooth, clean cuts. If you’re using a serrated knife or electric knife, make sure to apply consistent pressure and avoid tearing the foam.

Avoiding Tearing or Fraying

Soft foam can be prone to tearing or fraying along the edges. To prevent this, ensure that the tool is sharp and appropriate for the foam’s density. Using a saw with a fine-toothed blade or an electric carving knife will minimize damage to the foam’s edges.

Proper Cutting Speed

Cutting too quickly can result in jagged edges, while cutting too slowly can cause the foam to lose its shape. Finding the right cutting speed helps maintain control and ensures a clean cut. For softer foams, a slow and steady pace works best.

Conclusion

Cutting polyurethane foam doesn’t have to be a difficult task. With the right tools and techniques, you can achieve clean and precise cuts every time. Choose your tools based on the foam’s density and your specific cutting needs, and you’ll be able to handle any foam cutting project with ease.

-

Discover the most effective tools for cutting polyurethane foam, ensuring clean and precise cuts every time. ↩

-

Learn the proper technique for using a straight band knife to achieve smooth cuts in foam materials. ↩

-

Learn how these specialized blades offer precision and efficiency in cutting high-density materials, ensuring clean and accurate results. ↩