Are your band saw blades wearing out too fast? This problem costs you money in replacements and downtime. I'll show you how simple daily checks can easily fix this.

To increase band saw blade life by 20-30%, you must perform daily checks. This includes inspecting the saw chips, setting the correct cutting speed and feed rate for the material, ensuring proper blade tension and guidance, and using the right coolant.

These steps might seem basic. But the real savings come from doing them correctly and consistently. I've spent years perfecting this process in my own shop. Now, I want to walk you through my exact daily routine, step by step. Follow along, and you'll see the same amazing results. Let's get started.

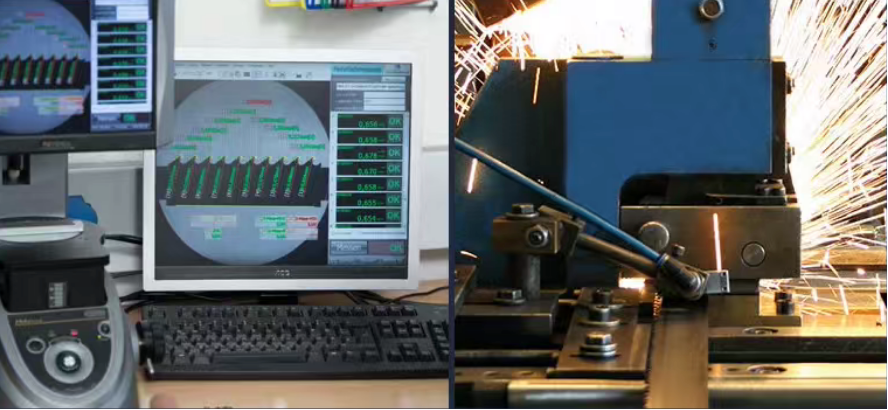

Are You Reading Your Saw Chips Correctly?

Do you ignore the metal chips your saw produces? This is a huge mistake. Those chips are telling you a story about your blade's health and cutting efficiency. Ignoring them leads to bad cuts and broken blades.

Reading your saw chips is the fastest way to diagnose cutting problems. Fine or powdery chips mean you need to increase the feed rate. Heavy or blue-colored chips mean the blade is overloaded. Thin, curled chips indicate ideal cutting conditions.

In my experience, the saw chips1 are like a report card for your cutting operation. They give you instant feedback. I teach every new operator to look at the chips before they look at anything else. It's the most important habit for extending blade life. You need to know what you're looking for. A quick glance can tell you if you're pushing the blade too hard or not hard enough. It's a simple visual check that prevents major problems.

Here is a simple guide I use every day:

| Chip Appearance | What It Means | Action to Take |

|---|---|---|

| Very Fine, Powdery | Blade is rubbing, not cutting. | Increase the feed rate2 or decrease the blade speed. |

| Thick, Heavy, or Blue | Blade is overloaded and overheating. | Decrease the feed rate2 or increase the blade speed. |

| Thin, Loosely Curled | Perfect cutting conditions3. | No change needed. Keep running. |

Making this check a habit will save you a fortune in blades.

Is Your Cutting Speed Optimized for the Material?

Using the wrong cutting speed is a common way to destroy a new blade. If you run the blade too fast on hard material, you'll burn out the teeth. If you run it too slow, you're just wasting time and not cutting efficiently.

Your cutting speed is determined by the material's hardness and its width. As a general rule, harder materials require a slower blade speed, while softer materials or smaller workpieces can be cut at a faster speed.

Think of it like this: the blade teeth need time to penetrate and remove material. When you're cutting a very hard alloy, like stainless steel, you have to slow down the blade speed. This gives each tooth enough time to do its work without creating too much heat. Excessive heat will soften the teeth and make them dull instantly. On the other hand, if you're cutting a small piece of soft aluminum, you can increase the speed. There is less resistance, so the blade can move faster without overloading. I always tell my team, "Match the speed to the material, not the other way around." It's a fundamental rule. Getting this right prevents premature wear and ensures a clean, efficient cut every single time. It's not about cutting fast; it's about cutting smart.

Is Your Feed Pressure Right for the Job?

You've set the right speed, but what about the pressure? Pushing too hard or too gently is another quick way to ruin your work and your blade. It's a balancing act that many people get wrong.

The correct feed pressure depends on the material type and its width. Harder or wider materials need more pressure to cut effectively. Softer or narrower materials require less pressure to avoid stripping the teeth or breaking the blade.

Getting the feed pressure4 right is crucial. The goal is for each tooth to take a proper-sized chip. If you use too little pressure on a hard material, the teeth will just rub against the surface. This doesn't cut. Instead, it creates a lot of heat and friction, which work-hardens the material, making it even tougher to cut. Your blade will get dull in no time. If you use too much pressure on a soft material or a thin-walled tube, you can overwhelm the teeth. This can cause the teeth to strip right off the blade, or worse, cause the blade to jam and break. I always start with a moderate pressure and watch the chips. The chips, as we discussed, will tell me if I need to add more pressure or back off a little. Finding that "sweet spot" is key to long blade life.

Why Is Proper Blade Tension So Critical?

Many operators install a new blade and forget about it. They don't check the tension. This is a critical mistake. A blade with the wrong tension is an accident waiting to happen.

Proper blade tension is essential for straight cuts and blade longevity. A new M42 bimetal blade should be tensioned to 250–300 N/mm². Always check it before the first cut and re-check it after a few initial cuts.

Think of the band saw blade as a long, thin beam. To cut straight, that beam needs to be stiff. Tension is what gives the blade its stiffness, or "beam strength." Without enough tension, the blade will flex and wander during the cut, leading to crooked, inaccurate parts. This is a common cause of scrap. On the other hand, too much tension puts excessive stress on the blade's body and the saw's components, like the wheels and bearings. This can lead to premature blade failure or even damage to your machine. I always follow a two-step process. First, I tension the new blade to the manufacturer's specification. Then, after making a few small cuts, I stop the machine and re-check the tension. The blade will often stretch slightly and "seat" itself on the wheels, causing the tension to drop. A quick re-tighten ensures it's perfect for the job.

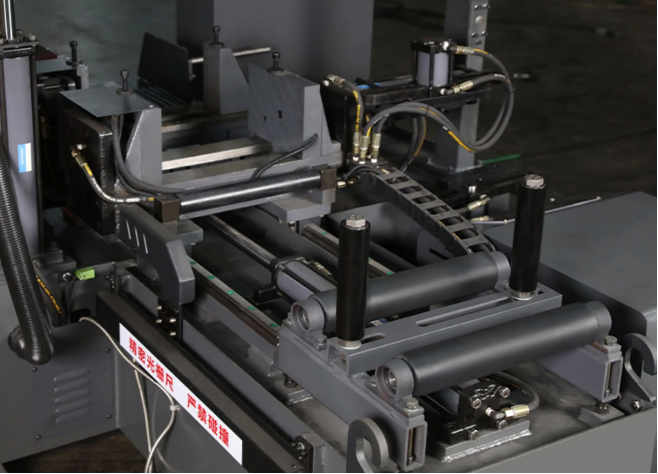

How Close Are Your Blade Guides to the Workpiece?

Your saw has blade guides for a reason, but are they positioned correctly? I often see guides set far apart, leaving a long span of the blade unsupported. This completely defeats their purpose.

Your cutting accuracy depends almost entirely on the blade guide setup. To maximize precision and blade stability, the guides must be positioned as close to the workpiece as possible without touching it.

The job of the blade guides5 is to support the blade and prevent it from twisting or deflecting under cutting pressure. The section of the blade between the guides is unsupported. The longer this unsupported span is, the more likely the blade is to wander, vibrate, or bow. This results in crooked cuts, poor surface finish, and can stress the blade, leading to premature failure. Before I start any cutting job, I make it a rule to adjust the movable guide arm. I bring it in so it's just a fraction of an inch away from the side of the material I'm cutting. This simple, 10-second adjustment dramatically increases the stiffness of the blade right where it matters most: in the cut. It's one of the easiest and most effective things you can do to improve cut quality and make your blades last longer.

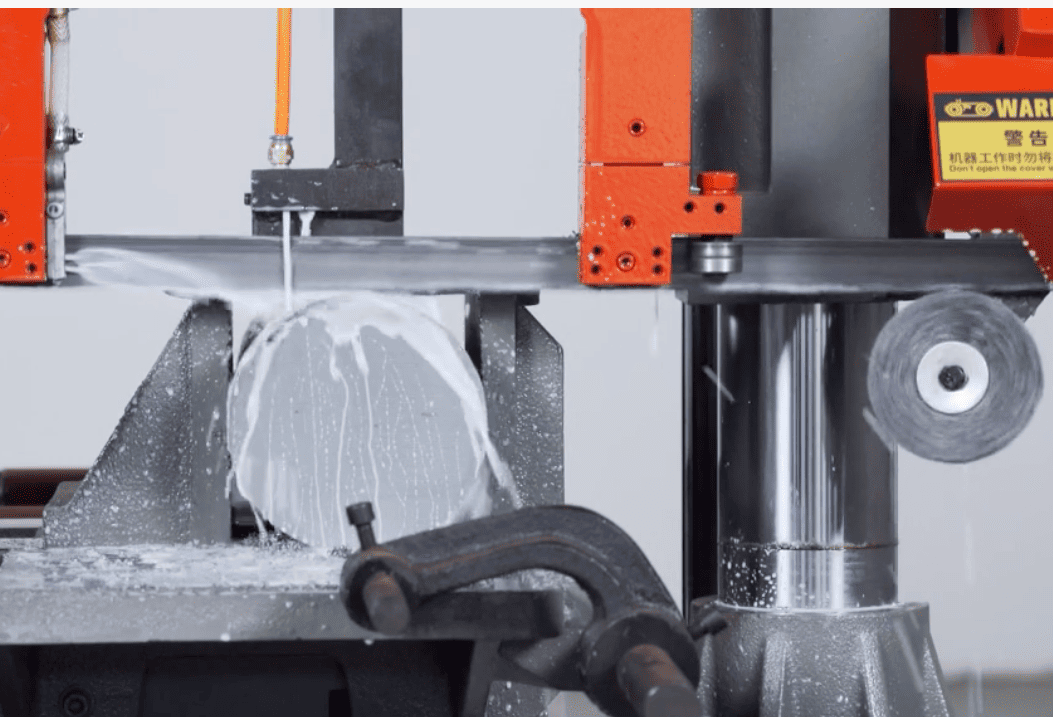

Are You Using the Right Coolant for Your Cuts?

Running a blade without coolant is like running a car engine without oil. You might get away with it for a short time, but disaster is inevitable. Heat is the number one enemy of a band saw blade.

Coolant and lubrication are essential for most metal cutting. They prevent overheating and help remove chips. However, some materials like cast iron, brass, and plastics can or should be cut dry or with air blast only.

The purpose of cutting fluid is twofold. First, it acts as a coolant6, carrying away the intense heat generated at the tooth's cutting edge. This prevents the teeth from softening and losing their sharpness. Second, it acts as a lubricant. It reduces friction between the blade and the workpiece and helps flush the chips out of the cut, preventing them from getting jammed in the gullets. Most ferrous and non-ferrous metals require a good quality coolant. However, there are exceptions.

| Material | Coolant Recommendation | Why? |

|---|---|---|

| Steels, Stainless, Aluminum | Yes, flood coolant | High heat generation, needs lubrication and flushing. |

| Cast Iron, Brass | No, cut dry or with air | Material is self-lubricating (graphite in cast iron). |

| Plastics, Graphite | No, cut dry or with air | Coolant can cause chemical reactions or cracking. |

I always make sure the coolant is mixed to the right concentration and that the nozzles are aimed directly into the cut. A weak mixture or a clogged line is useless.

Conclusion

By checking your chips, speed, pressure, tension, guides, and coolant daily, you will extend blade life. These simple habits save money, reduce downtime, and improve the quality of your work.

Understand how analyzing saw chips can help diagnose cutting issues and improve blade efficiency. ↩

Explore the relationship between feed rate and cutting efficiency to enhance your band saw operations. ↩

Understand how various cutting conditions can impact performance and blade longevity. ↩

Learn how to adjust feed pressure based on material type for effective cutting and blade care. ↩

Discover the best practices for positioning blade guides to ensure precision and stability during cuts. ↩

Get insights on the right coolant types for various materials to prevent overheating and enhance cutting. ↩