Struggling to cut tough, abrasive metals? Your blades wear out quickly, causing downtime and costing money. A carbide band saw blade is the powerful, long-lasting solution you need.

Carbide band saw blades are designed to cut a wide range of difficult materials. They excel at cutting hardened steels, nickel-based alloys, stainless steel, and other abrasive metals. These blades offer superior hardness and wear resistance for demanding industrial applications.

You now know carbide blades cut tough metals. But what specific types of metals and alloys can they really handle in a busy factory setting? Let's look closer at the details.

Can carbide blades handle common industrial metals and tough alloys?

Are standard blades failing on hard alloys? This breakage costs you time and money. Carbide blades are made for these tough jobs, increasing your efficiency and blade life.

Yes, carbide blades easily cut common metals like steel, aluminum, and copper. They are especially effective for tough materials like high-speed steel, cobalt alloys, and nickel-based superalloys. Their extreme hardness makes them ideal for materials that destroy conventional blades.

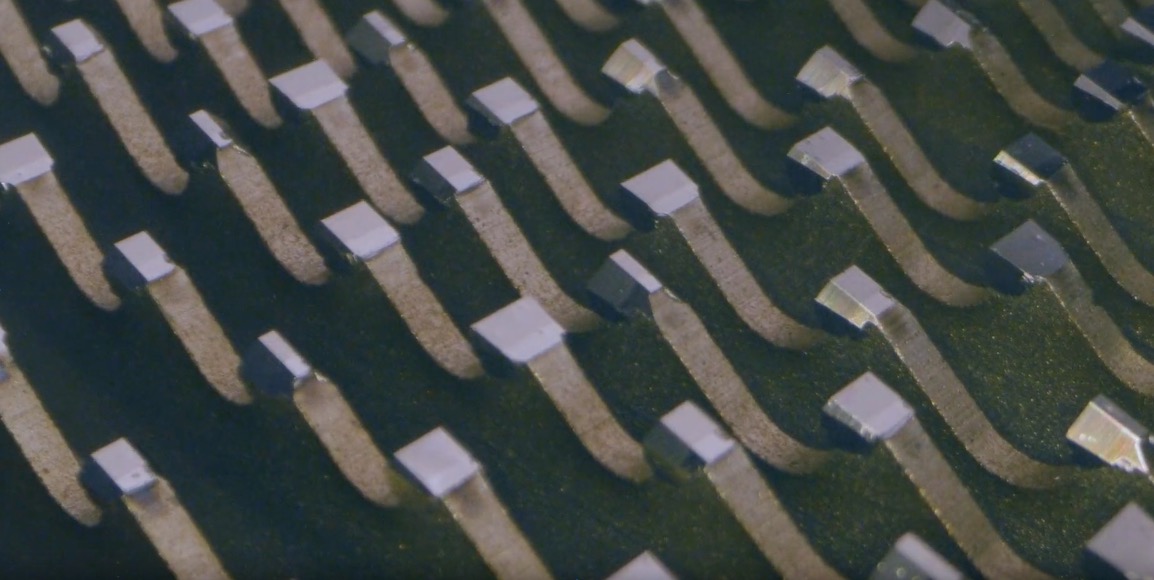

I've spent years helping factories find the right cutting tools. A common problem is cutting very hard or abrasive materials. Standard bi-metal blades struggle here. The teeth dull quickly. The blade can fail. This is where carbide blades make a huge difference. Their teeth are tipped with tungsten carbide, a very hard material. This means they stay sharp much longer, even when cutting difficult metals.

You can use them for everyday metals:

- Steel and Stainless Steel

- Iron and Cast Iron

- Aluminum

- Copper and Brass

But their real strength is with high-performance alloys. These materials are essential in aerospace and high-tech manufacturing, but they are a nightmare to cut. I've seen many shops destroy standard blades trying to cut them. A carbide blade is built for this punishment.

| Material Type | Standard Bi-Metal Blade Performance | Carbide Tipped Blade Performance |

|---|---|---|

| Hardened Steel | Wears out very quickly. | Cuts cleanly and lasts much longer. |

| Nickel-Based Alloys | Slow cutting speed, poor finish. | Faster cuts, excellent finish. |

| Titanium Alloys | Prone to blade failure and heat damage. | Handles the heat and abrasion well. |

| High-Speed Steel | Extremely difficult to cut, high wear. | Cuts effectively with proper setup. |

Choosing carbide for these jobs is not just an upgrade. It is a necessary step for efficient and profitable production when working with tough materials.

Are carbide band saw blades effective for cutting rebar and steel pipes?

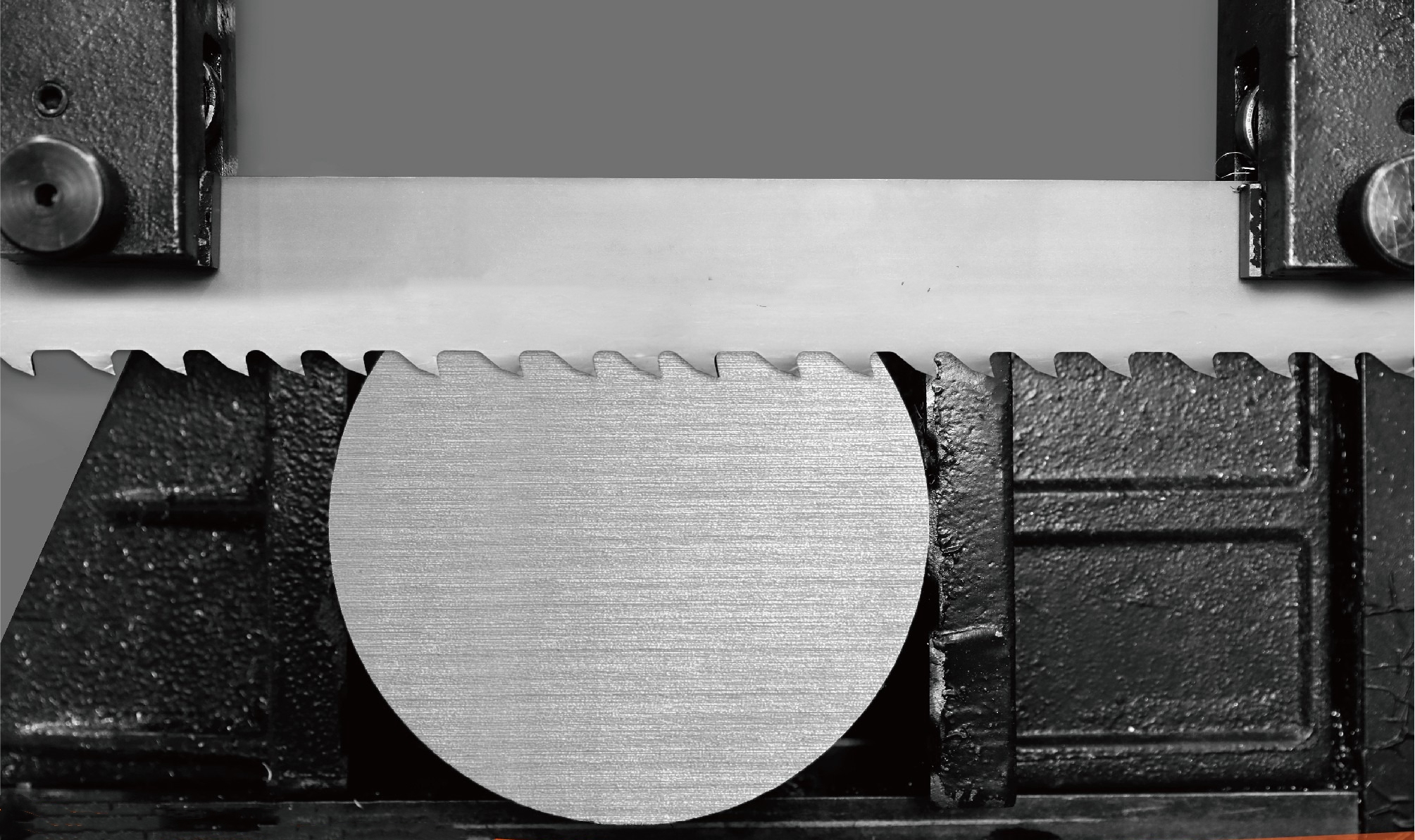

Cutting bundles of rebar or thick-walled pipes is a tough job. The interrupted cuts cause vibration and blade shock. This can break teeth and ruin blades prematurely.

Absolutely. Carbide blades are excellent for cutting rebar and various metal pipes and tubes. Their strong, wear-resistant teeth can handle the shock of interrupted cuts. This results in cleaner cuts, less vibration, and a much longer blade lifespan in these tough applications.

Cutting structural shapes like pipes, tubes, and rebar is a special challenge. It is not like cutting a solid block of steel. The blade enters and exits the material multiple times in a single pass. This is called an "interrupted cut." These interruptions create a lot of shock and vibration. On a standard blade, this shock can chip or strip the teeth right off.

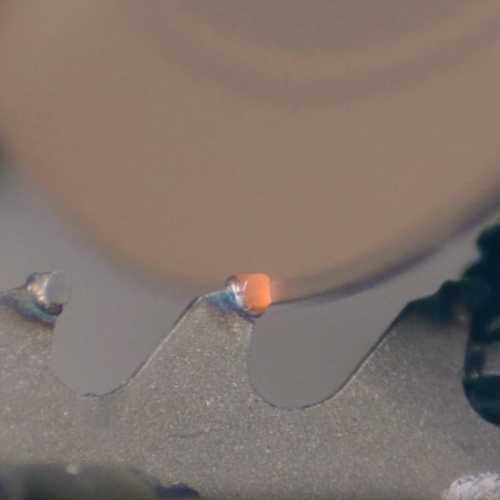

I have seen this happen many times in fabrication shops. A brand new blade is destroyed in just a few cuts. Carbide blades solve this problem. The carbide tips are brazed onto a tough, flexible backing. This combination gives you the best of both worlds. You get the extreme hardness of carbide to do the cutting. You also get the flexible backing to absorb the shock and vibration. This makes them perfect for cutting:

- Construction Materials: Bundles of steel rebar, structural steel beams.

- Piping and Tubing: Stainless steel pipes, copper tubes, aluminum tubing, thick-walled steel pipes.

The stability of the carbide tooth allows for smoother, more accurate cuts. This is critical in both construction and manufacturing where precision matters.

| Application | Challenge | Why Carbide Blades Work Better |

|---|---|---|

| Construction | Cutting bundles of rebar creates high vibration. | Strong teeth resist chipping from shock. |

| Manufacturing | Cutting thick-walled stainless steel tubes needs precision. | Stays sharp for high-volume, accurate cuts. |

Using a carbide blade in these situations means fewer blade changes, less wasted material, and more productive work for your team.

How do you choose the right carbide blade and settings for your material?

Using the wrong blade or settings can ruin your workpiece and destroy the blade. You waste material and money. Knowing how to choose correctly is key to success.

To choose the right blade, match the tooth pitch (TPI) to the material thickness. Use a variable pitch for structural shapes. Then, adjust your machine's cutting speed and feed rate for the specific material. Always use proper flood coolant to prevent overheating.

A great blade is only great if you use it correctly. I always tell my customers that the blade, the machine, and the operator are a team. Getting the settings right is just as important as buying a quality carbide blade.

First, let's talk about the blade itself. The most important factor is the tooth pitch, or Teeth Per Inch (TPI). A fine TPI (more teeth) is for thin materials. A coarse TPI (fewer teeth) is for thick materials. For cutting pipes or bundles, a variable pitch tooth is often best to reduce vibration.

Next are the machine settings. You must control the cutting speed (how fast the blade moves) and the feed rate (how hard you push the blade into the material). Different materials require different settings. For example, you cut stainless steel much slower than you cut aluminum. Your blade supplier should provide a chart with recommended settings.

Finally, lubrication is not optional. You must use a flood of coolant. This does two things. It keeps the blade and the material cool. It also flushes the chips out of the cut. Without proper coolant, a carbide blade will overheat and fail very quickly.

| Factor | Guideline | Why It's Important |

|---|---|---|

| Tooth Pitch (TPI) | Match to material thickness. Coarse for thick, fine for thin. | Prevents tooth stripping and ensures a smooth cut. |

| Cutting Speed | Slower for hard materials, faster for soft materials. | Prevents overheating and premature blade wear. |

| Feed Rate | Adjust for a good chip formation. Not too light, not too heavy. | Optimizes cutting efficiency and blade life. |

| Coolant | Use flood coolant generously and consistently. | Manages heat and clears chips from the cut path. |

While carbide blades are powerful, they have limits. For extremely hard materials like some ceramics or specialized superalloys, you might need an even more specific tool like a diamond grit blade. But for the vast majority of industrial metal cutting, a properly selected and used carbide blade is the best tool for the job.

Conclusion

Carbide band saw blades cut a huge range of tough metals and alloys. Choosing the right blade and settings will boost your factory's efficiency and save you money.