Are your band saw operations slow and producing poor results? You might be overlooking a critical setting. The right feed force can completely change your cutting efficiency and final product quality.

The feed force on a band saw directly controls cutting speed, cut quality, and blade life. Applying the correct force ensures a stable, efficient cut. Too much force causes rapid wear and heat, while too little force results in slow, poor-quality cuts and blade dulling.

Getting the feed force1 right seems like a small detail, but in my years of experience, it's one of the most common reasons why workshops struggle to get the performance they expect from their machines and blades. It’s the difference between a smooth, profitable operation and a frustrating, costly one. I want to walk you through exactly how this single setting has such a big impact. Let's break down what you need to know to master your machine and get the most out of every single blade you use.

How does feed force impact your cutting speed?

Struggling with slow cutting times that hurt your production schedule? The problem might not be your blade or machine, but the force you're applying. It's a common bottleneck in many workshops.

Feed force determines how fast the saw blade moves into the material. A higher, correct force increases your cutting speed and improves overall efficiency. A force that is too low will significantly slow down your operation, reducing your output and increasing costs per cut.

Let's dive deeper into this. I remember a client who was cutting large blocks of medium-carbon steel. They were frustrated because their cutting times were almost double what they expected. They thought they needed a more aggressive, expensive blade. When I visited their facility, I saw the issue immediately. They were being too cautious with their feed force1, worried they would damage the blade. This caution was actually counterproductive. The blade was barely biting into the material, essentially rubbing it instead of cutting. This not only slowed them down but also work-hardened the steel surface, making the next tooth's job even harder.

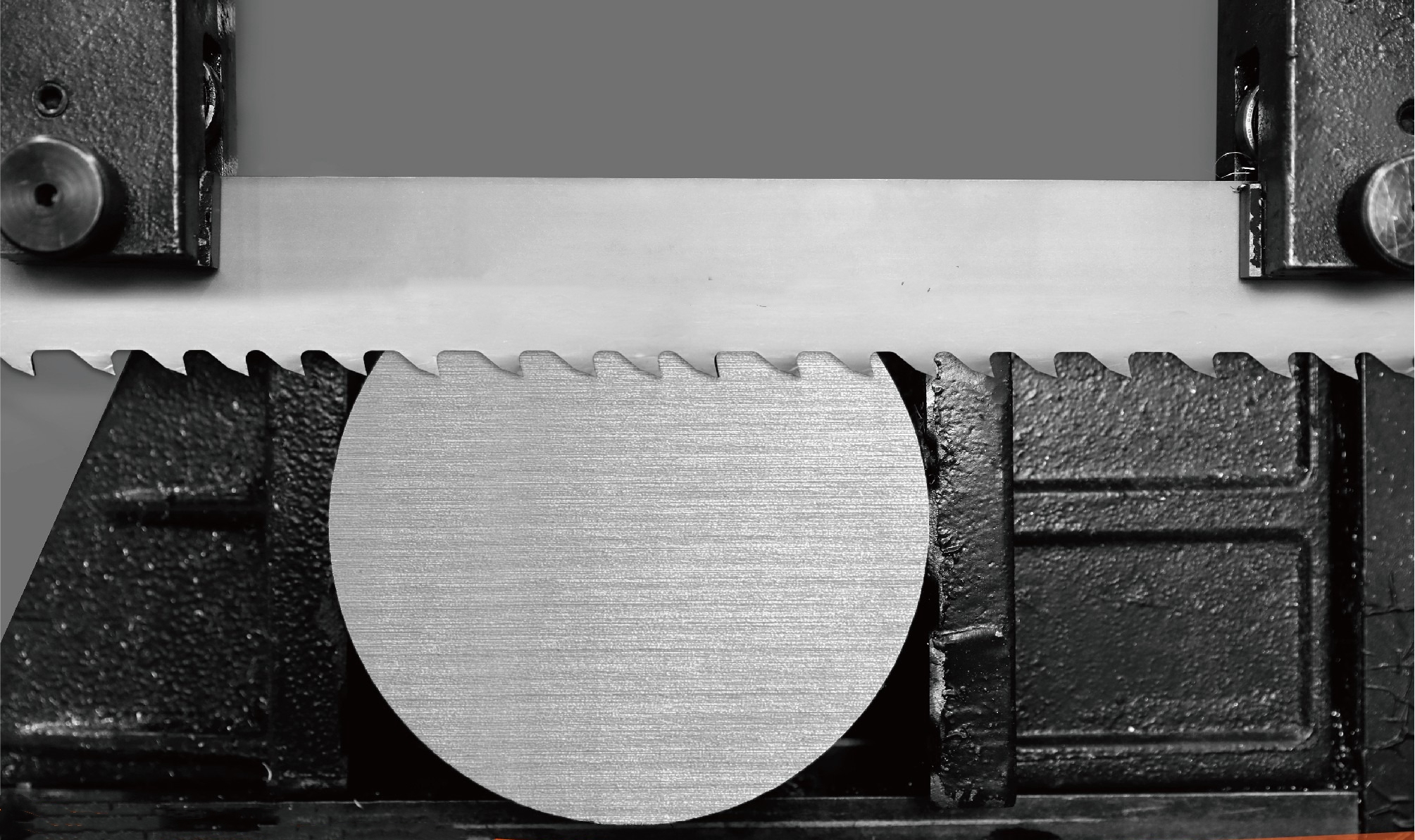

We increased the feed force1 gradually. The chips coming off the cut changed from fine powder to small, curled shavings—a perfect sign of an efficient cut. Their cutting time was reduced by 40%. The key is finding that sweet spot.

The Relationship Between Force, Speed, and Material

- Too Little Force: The blade teeth rub against the workpiece instead of penetrating. This creates friction and heat, dulls the teeth quickly, and can work-harden the material surface.

- Correct Force: The teeth penetrate the material properly, creating a distinct chip. This is the most efficient state for cutting, maximizing speed while minimizing blade wear.

- Too Much Force: The blade is pushed too hard, which can overload the teeth and the motor. This can lead to tooth stripping, blade breakage, or a crooked cut.

Here is a simple table to give you a general idea.

| Material Type | General Feed Force | Expected Chip Formation |

|---|---|---|

| Soft Metals (e.g., Aluminum) | Moderate to High | Thicker, curled chips |

| Mild/Low-Carbon Steel | Moderate | Well-formed, curled chips |

| Stainless/Hard Steels | Low to Moderate | Thinner, tighter curls |

The goal is to create a proper chip. By adjusting the feed force1 and watching the chips, you can dial in the perfect cutting speed2 for any job.

Does feed force change the quality of your cut?

Are your finished pieces coming off the saw with rough surfaces, burrs, or crooked edges? This poor quality forces you into extra finishing work, wasting time and money.

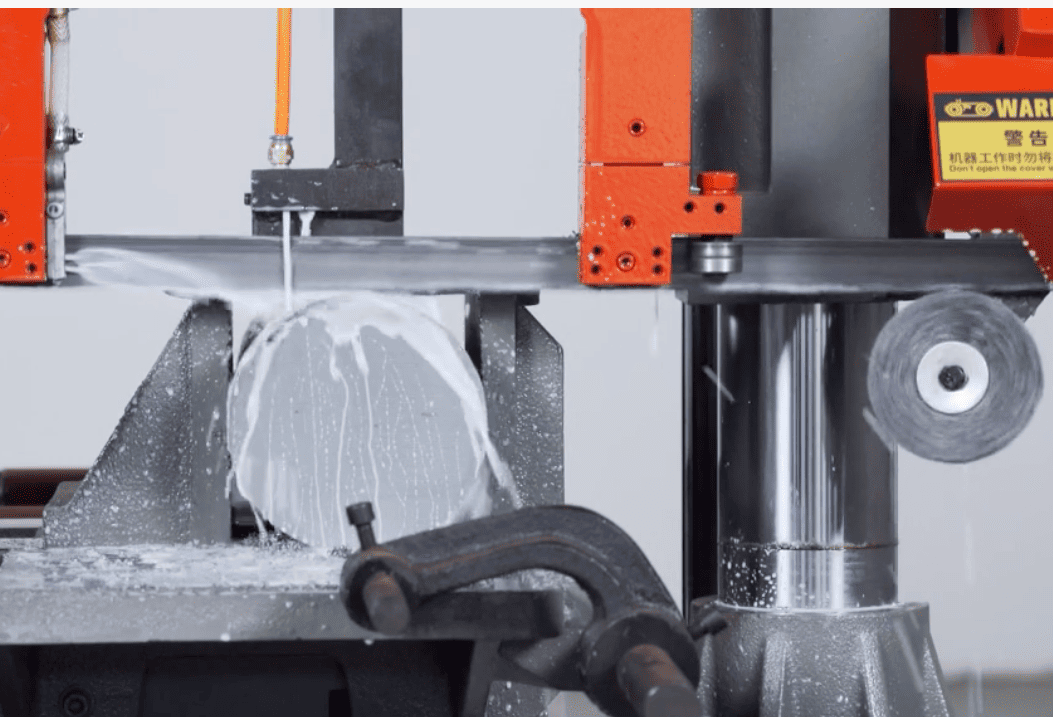

Yes, feed force is critical for cut quality. An unstable force, whether too high or too low, causes vibration and chatter. This leads to an uneven, inaccurate cut. A steady, appropriate feed force ensures a smooth, straight cut every time.

Let's explore this further. Cut quality isn't just about looks; it's about precision. If you are manufacturing parts that need to fit together, a crooked or rough cut can ruin the entire piece. I once worked with a fabrication shop that was having a high rejection rate on parts made from thick aluminum plate. The cuts were not perfectly straight, and the surface finish was terrible. They blamed the blades, the machine, everything but the process.

The problem was an inconsistent feed force. Their hydraulic feed system3 was old and wasn't delivering steady pressure. The blade would bite, then slip, then bite again. This created visible chatter marks on the cut surface and caused the blade to wander. We helped them service their feed system to provide consistent pressure. We also trained their operators to set the force based on the material thickness, not just a "one-size-fits-all" setting. The result was a dramatic improvement. Their cuts became smooth and straight, and their rejection rate dropped to almost zero. It all came down to controlling that force.

Factors Influencing Cut Stability

- Vibration and Chatter: When the feed force is too low, the blade doesn't stay engaged with the material. It can bounce or vibrate, creating a wavy or rough surface. This is known as chatter.

- Blade Wander: When the feed force is too high, it can overwhelm the beam strength of the blade. The blade will deflect or "wander" off a straight line, especially on taller workpieces. This results in a crooked cut.

- Burr Formation: An incorrect feed force often leads to excessive burrs on the exit side of the cut. A properly set force shears the material cleanly, minimizing the burr that needs to be removed later.

Think of it like using a handsaw. If you press too lightly, the saw skips. If you press too hard, the blade bends. You need that consistent, firm pressure to get a clean, straight line. The same principle applies to your band saw, just on an industrial scale.

Can the right feed force make your blade last longer?

Do you feel like you are constantly replacing band saw blades? The high cost and downtime can be a major drain on your business. This rapid wear is often a symptom of an incorrect setting.

Absolutely. Feed force directly impacts blade wear and fatigue. Too much force overloads the teeth and blade body, causing rapid dulling and breakage. The correct force minimizes friction and stress, significantly extending the usable life of your blade.

I can't stress this enough: managing feed force is the number one way to protect your investment in high-quality blades. A few years ago, a new customer called me, complaining that our blades were only lasting a few days. They were cutting hardened tool steel, which is a tough application, but the lifespan was still far too short. I asked about their parameters, and they told me they were running a very high feed force to "get through the cut faster."

They were trying to force the blade through the hard material. This extreme pressure was causing the sharp cutting edge of each tooth to chip and wear down almost immediately. The technical term is premature tooth dulling4. We had them reduce the feed force by about 30% and slightly increase the blade speed. The cutting time only increased by a small amount, but the blade life5 more than tripled. They were saving money not just on blades, but also on the downtime it took to change them.

How Force Affects Blade Wear

The damage from incorrect force happens in a few ways:

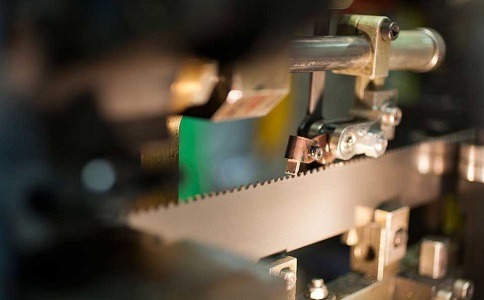

- Tooth Dulling and Chipping: As mentioned, excessive force puts too much pressure on the fine cutting edge of the tooth. Instead of shearing a chip, the tooth is crushed against the material, causing it to dull or fracture.

- Gullet Stress: The gullet is the curved area at the base of the tooth. It's designed to carry chips out of the cut. If the feed force1 is too high, it creates a very thick chip that can pack the gullet. This puts immense stress on the gullet area and can lead to cracks.

- Blade Fatigue: The band saw blade is constantly flexing as it goes around the wheels and straightening as it enters the cut. Pushing too hard adds another major stressor. This combination of bending and high cutting stress accelerates metal fatigue, eventually causing the blade body to snap.

Here is a table showing the cause and effect:

| Feed Force Setting | Primary Wear Type | Result |

|---|---|---|

| Too Low | Rubbing/Abrasion | Premature dulling, slow cutting |

| Correct | Normal Flank Wear | Longest possible blade life, efficient cutting |

| Too High | Tooth Chipping, Fatigue | Stripped teeth, cracked gullets, broken blades |

By finding the right balance, you allow the blade to work as designed, ensuring each tooth does its share of the work cleanly and efficiently. This simple adjustment is the secret to longer blade life5.

How does feed force generate heat and affect the blade?

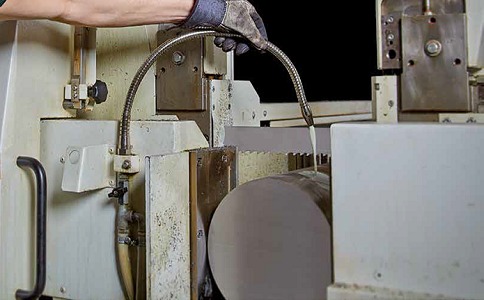

Have you ever seen smoke coming from a cut or noticed discoloration on your blade or workpiece? This excessive heat is a danger sign that can quickly destroy a blade and ruin your material.

A higher feed force increases the friction between the blade and the material. This friction generates heat. Too much heat can soften the blade's teeth, making them dull instantly, and can even cause the blade body to deform or break.

Let's get into the physics of it, but in simple terms. Cutting metal is a process of shearing and deforming material, which always generates heat. The goal is to manage that heat. Most of the heat generated should be carried away by the chips. When your feed force is correct, you create a good chip that takes the heat with it. However, if your feed force is wrong, the heat builds up in the worst possible place: the blade itself.

I've seen blades come off a machine glowing blue. That blue color is a sign that the steel has been heated to a temperature where its temper is ruined. The hardened teeth become soft, and a soft tooth can't cut hard metal. If the feed force is too high, the friction is immense, creating a surge of heat. If the feed force is too low, the blade rubs instead of cuts, also creating friction and heat6 but without creating a chip to carry it away. Both extremes are bad. Coolant can help, but it can't solve a problem caused by incorrect force.

The Cycle of Heat and Failure

Think of it as a destructive cycle.

- Incorrect Force: You apply too much (or too little) feed force.

- Increased Friction: This causes excessive friction in the cut.

- Heat Buildup: The temperature of the blade's cutting edge rises dramatically. Coolant can't reach the exact point of contact effectively.

- Tooth Softening (Loss of Hardness): The high heat anneals the hardened steel of the tooth tip, making it soft.

- Rapid Dulling: The now-soft tooth is wiped out almost instantly by the material it's trying to cut.

- Increased Force Required: A dull blade requires even more force to cut, which just accelerates the cycle, leading to catastrophic failure.

Proper feed force, combined with the correct blade speed and adequate coolant flow7, keeps this cycle from ever starting. It ensures the heat is managed properly, protecting both the blade and the workpiece from thermal damage8. It’s a critical part of a stable and efficient cutting process.

Conclusion

In summary, feed force is not just a minor setting. It is a fundamental control that directly impacts your cutting speed, quality, blade longevity, and heat generation9. Mastering it saves money.

Understanding feed force is crucial for optimizing cutting efficiency and improving the quality of your band saw operations. ↩

Learn how adjusting feed force can significantly enhance your cutting speed, boosting productivity and reducing costs. ↩

Explore how a well-maintained hydraulic feed system ensures consistent feed force for better cutting results. ↩

Understand how incorrect feed force settings can lead to premature tooth dulling, affecting cutting performance. ↩

Discover how proper feed force settings can extend the life of your blades, saving you money on replacements. ↩

Explore how feed force affects friction and heat, and how to control these factors for better cutting. ↩

Find out how coolant flow can help manage heat generated by feed force, protecting your blade and material. ↩

Understand how excessive feed force can cause thermal damage, compromising blade integrity and performance. ↩

Understand the relationship between feed force and heat generation, and how to manage it effectively. ↩