Are you frustrated by new band saw blades cracking right after installation? This wastes money and causes significant downtime. Let's find out the common, fixable causes.

Early cracks on a new band saw blade are often caused by improper break-in procedures, incorrect blade tension, or poorly adjusted guide arms. Skipping the break-in or overtightening the blade puts excessive stress on it, leading to premature failure and cracks from the teeth or back.

I've been in this business for a long time, and I've seen this problem countless times. It's almost always a setup or operational issue, not a faulty blade. The good news is that these are easy fixes once you know what to look for. Let's dig into the details and get your blades lasting as long as they should.

Are You Breaking In Your New Blades Correctly?

You install a new blade and it cracks within hours. It feels like you just threw money away. A proper break-in routine is your first line of defense.

Yes, every new band saw blade must go through a break-in, or run-in, period. This process gently hones the sharp tooth edges, preventing premature chipping and extending blade life. Skipping this critical step is a major reason for early cracks and failure.

I remember a client who called me, very upset. He was going through blades like crazy, and they were cracking from the tooth gullets. I asked him about his break-in process. He said, "What break-in process?" That was the whole problem right there. A new blade's teeth are incredibly sharp, almost too sharp. If you go full speed into a hard material right away, the teeth can chip or fracture. These tiny fractures can then grow into full-blown cracks that destroy the blade. The break-in period smooths these microscopic sharp edges and prepares them for heavy work.

How to Break In a Blade

The goal is to reduce the cutting feed rate1e](https://en.wikipedia.org/wiki/Bandsaw)%%%FOOTNOTE_REF_2%%% for the first 5-15 minutes of cutting, or for the first 50-100 square inches of material. This allows the teeth to develop a small, stable radius.

| Material Type | Break-in Feed Rate | Break-in Speed |

|---|---|---|

| Mild Steels & Structurals | 50% of normal feed rate2 | 100% of normal speed |

| Stainless & Tool Steels | 75% of normal feed rate2 | 75% of normal speed |

| Aluminum & Soft Metals | 50% of normal feed rate2 | 100% of normal speed |

This simple step prepares the teeth for the tough work ahead. It is the single most important thing you can do to prevent early cracks and get your money's worth from every blade.

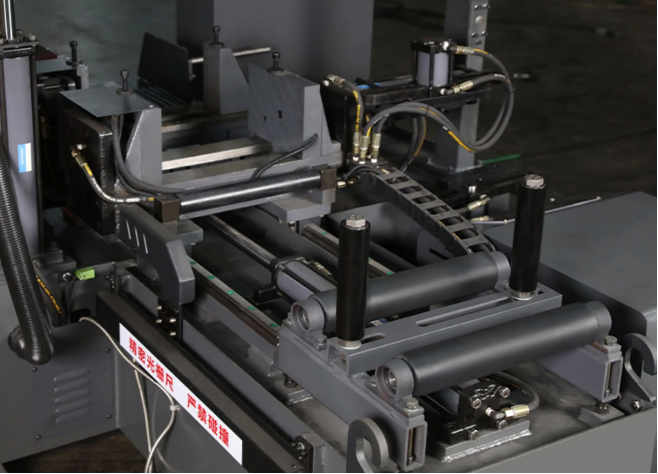

Is Your Blade Tension Set Too High?

You tighten the blade until it feels "right," but it still cracks. "Right" is subjective and can lead to costly damage. Let's learn to set tension correctly and consistently.

Overtightening is a common cause of cracks, especially from the back of the blade. Excessive tension puts the blade body under constant stress, making it brittle and prone to fatigue fractures. The goal is to have just enough tension to cut straight, but no more.

Think of the blade like a rubber band. If you stretch it too far, it becomes weak and will snap easily. The same thing happens to your band saw blade. Many operators just crank the tension handle without thinking about the actual force they are applying. This puts the blade's body under extreme stress, even when it's just sitting idle. Then, when you add the stress of cutting, bending around the wheels, and heat, a crack is almost inevitable. I always tell my team, "Tighter is not always better." The back of the blade cracks first because it is under the most strain.

Finding the Right Tension

The correct tension ensures a straight cut without over-stressing the blade. There are two ways to get there.

| Method | Description | Target Value |

|---|---|---|

| The "Feel" Test | Install the blade and tighten it. Push on the side of the blade body between the guides. It should have a little bit of spring or give to it. It shouldn't feel rigid. | Subjective, best for very experienced operators. |

| Tension Gauge | This is the most accurate method. A small instrument measures the tension directly on the blade. It removes all the guesswork and ensures consistency. | Around 300 N/mm² (or 25,000-35,000 PSI, always check blade manufacturer specs). |

Using a tension gauge3 is a small investment that pays for itself quickly by preventing blade failures4. It's the professional way to ensure consistency, especially if you have multiple operators or shifts.

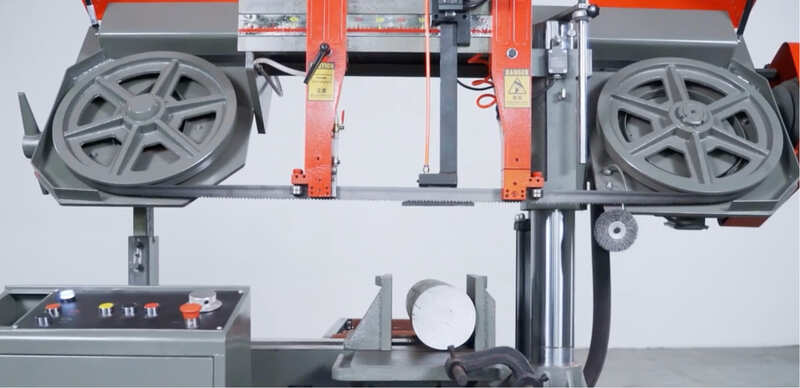

Are Your Guide Arms Positioned Too Far Apart?

Your saw is set up, but blades are still cracking. You might be overlooking a simple adjustment that is causing major stress. It's time to check your guide arm spacing.

The distance between your guide arms has a huge impact on blade stability and life. If they are too far apart, the blade has more room to twist and flex during a cut. This constant twisting motion leads to metal fatigue and cracks.

I once visited a workshop where the operator had the guide arms set as wide as the machine would allow. He thought it made it easier to load large workpieces. But what he was actually doing was creating a long, unsupported span of blade. As the blade cut, it would twist back and forth. This repetitive stress is a killer for any metal. The cracks were appearing right behind the gullets because that's where the twisting force was at its highest. It's a simple physics problem. A shorter span is much stronger and more rigid than a long one.

Correct Guide Arm Setup

The rule is simple: keep the guides as close as possible to the workpiece for every cut.

| Step | Action | Why it's important |

|---|---|---|

| 1. Position Workpiece | Place the material you are about to cut into the saw's vise and secure it. | This sets your cutting area and defines the blade's path. |

| 2. Adjust Arms | Move the adjustable guide arm so it is about 1 cm (or half an inch) away from the side of your workpiece. | This minimizes the unsupported blade span, reducing twist and vibration. |

| 3. Check Clearance | Make sure the saw frame can still lower fully without the guide arm assembly hitting the vise or workpiece. | This prevents machine damage and ensures a complete cut. |

This quick adjustment takes only a few seconds but dramatically reduces the twisting stress on your blade. It directly translates to longer blade life5 and straighter, more accurate cuts.

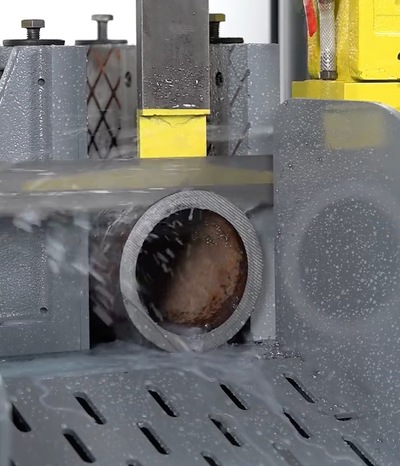

Could Other Machine Settings Be Causing the Cracks?

You've checked break-in, tension, and guides, but blades still fail. It's frustrating when you can't find the single cause. Let's look at the complete system.

Sometimes, it's not one big thing but a combination of smaller issues. An incorrect feed rate, excessive speed, or worn guide blocks can all contribute to blade stress and cracks. A holistic check of your machine setup is necessary to solve the problem for good.

A band saw is a complete system. Every part has to work together. If one thing is off, it puts stress on everything else. For example, if your feed rate2 is too high, you are forcing the teeth into the material. This can cause the blade to chatter and vibrate, leading to micro-fractures. If your blade speed6 is too fast for the material, you generate excessive heat. This heat can soften the blade's backer, making it weak and prone to cracking. Even something as simple as worn guide blocks7 can be the culprit. If they don't support the blade properly, it will vibrate and twist no matter how well you set the arm spacing.

Quick System Check

Here are other factors to review to stop cracks from forming.

| Factor | What to Check | Impact if Incorrect |

|---|---|---|

| Feed Rate | Is it too aggressive for the material? Are you hearing chattering or seeing burn marks on the cut? | Causes tooth stripping, vibration, and stress cracks. |

| Blade Speed | Is the speed (SFPM or M/Min) correct for the material type and thickness? | Generates excessive heat, softening the blade and causing premature failure. |

| Guide Blocks | Are the carbide or roller guides worn, chipped, or too loose/tight against the blade? | Allows blade vibration, poor support, and inaccurate cuts. |

| Coolant | Is the flow adequate and aimed directly into the cut and onto the blade? Is the concentration correct? | Prevents heat buildup, which is a major cause of blade fatigue and failure. |

Treating the saw as a whole system, not just a collection of parts, is the key to mastering your cutting process and maximizing blade life.

Conclusion

In short, blade cracks are usually from operational mistakes, not bad blades. Master these simple skills, and you will use your blades longer, better, and more effectively.

Understanding feed rates can help you make adjustments that prolong blade life and improve cuts. ↩

Knowing the right feed rate for materials can prevent blade damage and improve cutting quality. ↩

Using a tension gauge ensures accurate blade tension, which is vital for optimal performance. ↩

Understanding the causes of blade failures can help you implement preventive measures. ↩

Exploring factors that affect blade life can lead to better maintenance and cost savings. ↩

Understanding blade speed is crucial for preventing overheating and ensuring effective cuts. ↩

Worn guide blocks can lead to blade vibration and inaccuracies; learn how to check and maintain them. ↩